In mold making, we usually hear casting and forging. What is the difference between the two manufacturing processes?

Casting is only used for large forgings. Casting is an as-cast structure with large columnar crystals and loose centers. Therefore, it is necessary to break the columnar crystal into fine crystal grains by large plastic deformation, and loosely compact, in order to obtain excellent metal structure and mechanical properties.

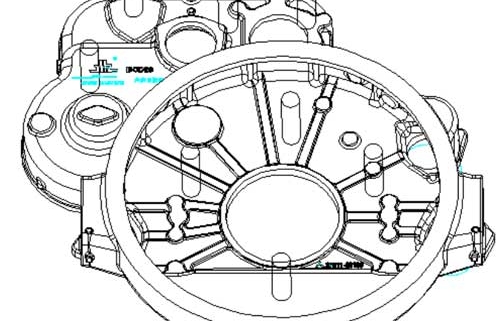

Forging is a processing method in which a forging press is used to apply pressure to a metal blank to cause plastic deformation to obtain a forged piece having a certain mechanical property, a certain shape and a size. Forging and stamping are of the same plastic processing properties, collectively referred to as forging.

First, casting

Casting is a metal liquid forming process, in which a molten liquid alloy is injected into a pre-prepared mold to form a casting after cooling and solidification. The casting can be subdivided into sand casting, pressure casting, investment casting, shell casting according to the process. , lost foam casting, low pressure casting, gravity casting, etc.

The casting mold is a process in which a metal is smelted into a liquid that meets certain requirements and poured into a mold, and after cooling and solidifying and clearing, a casting (part or blank) having a predetermined shape, size and performance is obtained, which is a modern machine. The basic process of manufacturing industry.

The blank produced by casting has low cost, and it can show its economicality for parts with complicated shapes, especially those with complex inner cavity; at the same time, it has wide adaptability and good comprehensive mechanical properties. However, materials required for casting production (such as metal, wood, fuel, modeling materials, etc.) and equipment (such as metallurgical furnaces, sand mixers, molding machines, core making machines, falling sand machines, shot blasting machines, cast iron plates, etc.) It is polluted by dust, harmful gases and noise.

1. There are many kinds of castings, which are habitually divided according to the modeling method:

(1) Ordinary sand casting, including wet sand type, dry sand type and chemical hardening sand type.

(2) Special casting, according to the modeling material, can be divided into special castings with natural mineral sand as the main modeling material (such as investment casting, clay casting, foundry casting, negative pressure casting, solid casting, ceramics). Type casting, etc.) and special castings with metal as the main casting material (such as metal casting, pressure casting, continuous casting, low pressure casting, centrifugal casting, etc.).

2. The casting process usually includes:

(1) Preparation of molds (containers that make liquid metal into solid castings). The molds can be classified into sand type, metal type, ceramic type, mud type, graphite type, etc. according to the materials used; Semi-permanent and permanent. The pros and cons of casting preparation are the main factors affecting the quality of castings;

(2) melting and casting of cast metal, cast metal (casting alloy) mainly including cast iron, cast steel and cast non-ferrous alloy;

(3) Casting treatment and inspection, casting treatment includes removal of foreign objects on the surface of the core and casting, removal of the riser, burrs and burrs, as well as heat treatment, shaping, anti-rust treatment and roughing.

Second, forging

The forging die is a processing method that applies pressure to the metal blank by using a forging machine to plastically deform it to obtain a forging having a certain mechanical property, a certain shape and a size, and is one of the two major components of the forging.

Through forging, it can eliminate the as-cast looseness and weld hole of the metal, and the mechanical properties of the forging are generally superior to those of the same material. For important parts with high load and severe working conditions in machinery, forgings are often used except for the available rolled sheets, profiles or welded parts.

1. Forging is divided according to the forming method

(1) Open forging (free forging)

The impact force or pressure is used to deform the metal between the upper and lower stellite irons (anvil) to obtain the required forgings, mainly hand forging and mechanical forging.

(2) Closed mode forging

The metal blank is subjected to compression deformation in a forging die having a certain shape to obtain a forged piece, which can be classified into die forging, cold heading, rotary forging, extrusion, and the like.

2. According to the deformation temperature

Forging can be further divided into hot forging (processing temperature is higher than the recrystallization temperature of the blank metal), warm forging (below the recrystallization temperature) and cold forging (normal temperature).

The forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, titanium, copper and the like and alloys thereof. The original state of the material is bar, ingot, metal powder and liquid metal. The ratio of the cross-sectional area of the metal before deformation to the area of the die after deformation is called the forging ratio. Proper selection of forging ratios has a lot to do with improving product quality and reducing costs.

Forging according to the temperature of the blank during processing can be divided into cold forging and hot forging. Cold forging is generally processed at room temperature, and hot forging is processed at a higher recrystallization temperature than the billet metal. Forging, which is sometimes heated, but the temperature does not exceed the recrystallization temperature, is called warm forging. However, this division is not completely uniform in production.

The recrystallization temperature of steel is about 460 ° C, but 800 ° C is generally used as the dividing line, and higher than 800 ° C is hot forging; between 300 and 800 ° C is called warm forging or semi-hot forging.

Forging can be divided into free forging, die forging, cold heading, radial forging, extrusion, forming and rolling, roll forging, and boring according to the forming method. The deformation of the blank under pressure is basically free from external restrictions, also called open forging; the blank deformation of other forging methods is limited by the mold, called closed mode forging. The forming tool such as forming rolling, roll forging, boring and the like have a relative rotational motion with the blank, and the blank is subjected to point-by-point and asymptotic pressurization and forming, which is also called rotary forging.

The forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium and the like and alloys thereof. The raw state of the material is bar, ingot, metal powder and liquid metal.

Generally, small and medium-sized forgings use round or square bars as blanks. The grain structure and mechanical properties of the bar are uniform and good, the shape and size are accurate, and the surface quality is good, which is convenient for mass production. As long as the heating temperature and deformation conditions are properly controlled, high-quality forgings can be forged without requiring large forging deformation.

By applying static pressure to the liquid metal poured in the mold to solidify, crystallize, flow, plastically deform and form under pressure, a die forging of desired shape and performance can be obtained. Liquid metal die forging is a forming method between die casting and die forging, and is particularly suitable for complex thin-walled parts which are difficult to form by general die forging.

Different forging methods have different processes, among which the hot forging process has the longest process, and the general sequence is: forging blanking; forging billet heating; roll forging blank; die forging; trimming; intermediate inspection, inspection forgings Dimensions and surface defects; forging heat treatment to eliminate forging stress and improve metal cutting performance; cleaning, mainly to remove surface oxide scale; correction; inspection, general forgings undergo appearance and hardness inspection, important forgings also undergo chemical composition analysis , mechanical properties, residual stress and other tests and non-destructive testing.