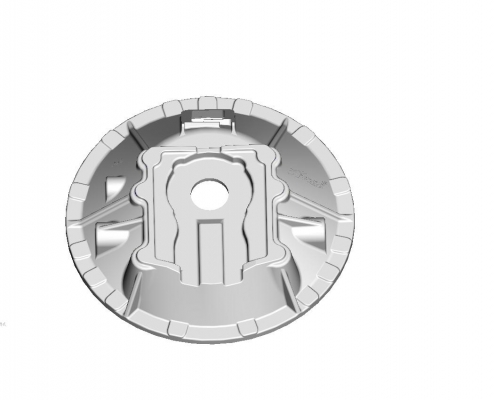

Clutch housing mold

The clutch housing is the outer casing that connects, supports, and protects the clutch components. The clutch assembly is formed with a clutch friction plate, a spring, a release bearing, a shift fork, and a separation claw.

| Place of Origin: Henan, China (Mainland) | Brand Name: Liushi&OEM | Model Number: Customized |

| Product Name: Clutch housing mold | Material: Aluminum | Surface treatment: TEFLON surface coating |

| Service:

Customer’s Drawings |

Certification: ISO9001 | Dimensions: Customized Sizes |

| Application:

Machinery Parts |

Process: Lost Foam Casting | Lead Time: 45 Days |

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

The lost foam casting process is widely used, and the clutch housing mold is also a customized product, which can be customized according to the needs of users.

|

Mould material

|

ZL106 aluminium casting alloy,7075 reflectal

|

|

Casting alloy

|

Cast aluminium,Cast steel,Grey iron,Ductile iron

|

|

Cavity qty

|

Single cavity, Multiple cavity, Unit cavity

|

|

Process

|

Adopts CNC, WEDM-LS, drill machine, polishing machines, lathe, milling machine,etc.

|

|

Treatment

|

TEFLON surface coating treatment and Heat treatment and etc

|

|

Design software

|

AutoCAD, UG, Pro-E, Solidworks, etc

|

|

Lead time

|

15to 30 days for samples, exact time depends on mold complexity

|

|

Forming machine

|

Cold chamber die-casting machineS180T/280T/500T/800T/1250T

Hot chamber die-casting machines58T/88T168T

|

|

Mold life

|

30000 to 50000 depend on products

|