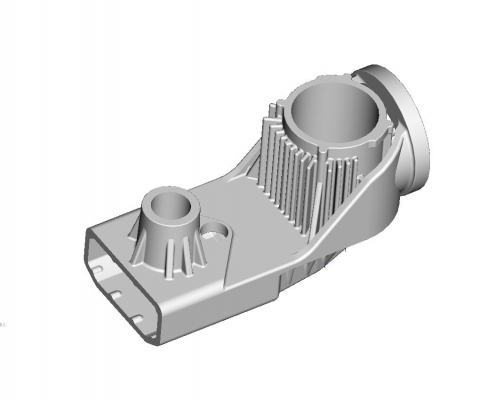

Gearbox mold

The transmission housing and the front and rear cover bodies are the main components of the transmission. The outer shape of the transmission case is shown in Figure 1. The geometry of the casting is complex, the boss and the assembly position are numerous, and the relevant dimensional accuracy is high. The material is H T250.

Product research casting technology design

(1) Selection of process parameters for core preparation

1 casting shrinkage

2 casting draft slope

3 casting processing allowance

(2) The main points of the production and operation of the core

1 The amount of sand in the casting sand box: the ratio of the thickness of the sand layer to the wall thickness of the casting is about 2.5:1.0

2 Master the on-duty sand temperature, temperature and climatic conditions, adjust the formula according to the actual situation, and prepare for production.

3 The core of the mud should be hollowed out as much as possible, and the nylon should be drained at the place where it is not easy to be hollowed out to ensure the smooth ventilation system. The upper surface of the mold should be inserted with ○10mm air eyes to facilitate the exhaust.

4 Strictly control the mold time and check the strength, avoid the hardening enough to cause the sticking mold, or the hardening is too much and the demoulding is difficult, so that the shape (core) is broken.

5 If a block-shaped type (core) appears, it is repaired by bonding with a towel after 1 hour of hardening. If the irregular part is not formed, the sand will be expanded into an inverted wedge shape. The part repaired with the new sand should have a compressive strength of >2.0 MPa, and the geometrical dimensions must be correct.

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

In order to reduce the wear and power loss of parts caused by internal friction, it is necessary to inject lubricating oil into the casing and lubricate the working surfaces of the gear pairs, shafts and bearings with splash lubrication. Therefore, there is a fuel filler port on one side of the casing and a drain plug at the bottom, and the oil level is controlled by the position of the fuel filler port. A radial oil hole is drilled in the first-axis constant meshing gear and the third gear on the second shaft, and the reverse intermediate gear and the intermediate shaft often mesh with the gear end face of the transmission gear to open a radial oil groove for lubricating the rolling portion Needle bearing. In order to prevent the lubricating oil from flowing into the clutch from the gap between the first shaft and the bearing cover and affecting the friction performance, an oil seal assembly is installed in the bearing cover, and an oil return groove is arranged in the inner hole of the bearing cover to prevent oil leakage. To prevent oil from flowing out from the rear end of the second shaft. An oil seal assembly is mounted in the rear bearing cap of the transmission. A gasket is placed at the joint surface of each of the bearing cap, the back cover, the upper cover, the front and rear casings, and the like, and a sealant is applied to prevent oil leakage. In order to prevent oil leakage due to oil temperature and pressure increase during operation of the transmission, a venting plug is installed on the shifting mechanism seat and the rear bearing cover of the transmission.