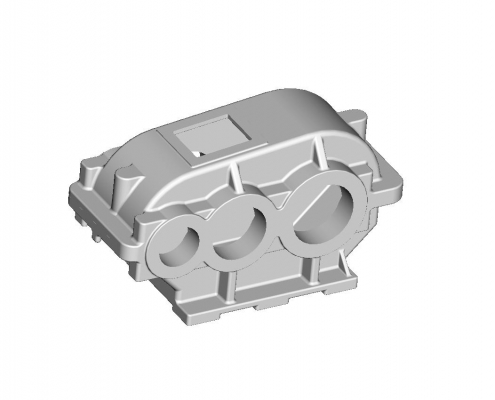

Reducer housing mold

The lost foam mold is a casting processing mold, which is a solid casting of a foam plastic mold using a non-bonding agent dry sand combined with vacuuming technology. The foam model similar in shape and shape of the casting is bonded and combined into a model cluster, and the refractory coating is applied. After drying, it is buried in dry quartz sand for vibration modeling, pouring under negative pressure, gasifying the model, liquid metal occupies the model position, solidification and cooling to form a new casting method for castings, but due to the different models of the reducer housing, However, the mold of the lost mold is fixed, which increases the cost of casting to a certain extent, and cannot be adjusted as needed, and the applicability and practicality are limited.

Packaging & Delivery

- Packaging Details: Wood box, suit for long distance transportation

- Port: Any Chinese Sea Port

- Lead Time: 20-30 days

The lost mode of the gear unit housing with reasonable structure and good stability is designed to solve the technical problem that the lost mode can not be adjusted in the conventional technology. The lost mold of the reducer housing is cast, including a bottom template and at least three side templates, the bottom of the side template is connected with the edge of the bottom template, and the dovetail card is arranged at the edge of the bottom template, and the bottom end side of the side template has The dovetail card slot has a card vertical bar and a card vertical slot on the symmetrical side of the side template, and the adjacent side template is connected by the card vertical bar and the card vertical groove, and the liquid guiding body is connected up and down in the side template. The hole has a liquid inlet connected to the liquid guiding hole.