Алюминиевые листы с предварительно окрашенным покрытием (ППАЛ) стали краеугольным камнем в современном строительстве, Автомобиль, и промышленные проекты. Сочетание легкости и прочности, устойчивость к коррозии, и эстетическая универсальность, эти листы экономят время и деньги, обеспечивая при этом стабильное качество.. Но что именно входит в производство этих высокопроизводительных алюминиевых листов?, и почему им доверяют во всем мире? В этой статье, мы изучаем весь производственный процесс, методы нанесения покрытий, и стандарты качества предварительно окрашенных алюминиевых листов.

Что такое алюминиевые листы с предварительно окрашенным покрытием?

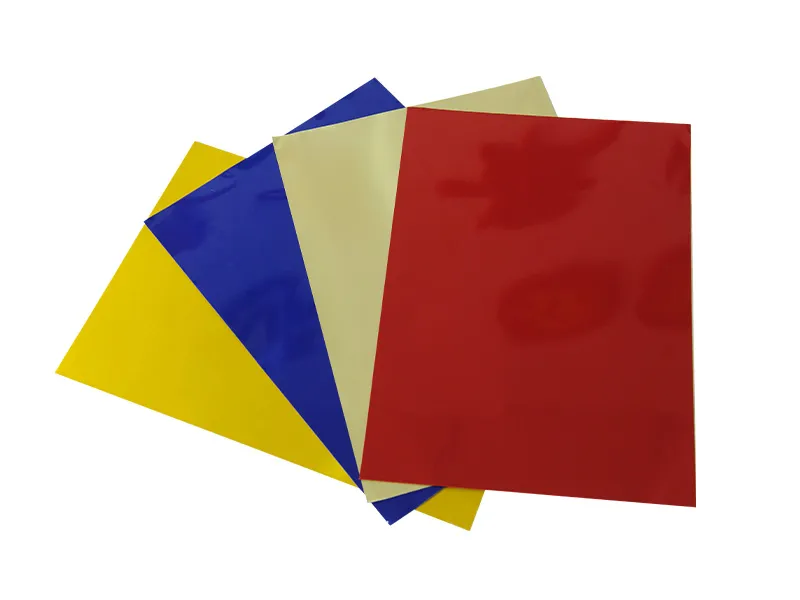

Предварительно окрашенные алюминиевые листы представляют собой алюминиевые подложки, покрытые защитным и декоративным слоями краски, прежде чем они попадут к клиенту.. В отличие от традиционного алюминия, который необходимо покрасить после изготовления, PPAL поставляется готовым к использованию, предложение:

Отличная устойчивость к коррозии и атмосферным воздействиям

Длительная стабильность цвета и сохранение блеска.

Легкие, но структурно прочные свойства

Экономическая эффективность за счет сокращения затрат на покраску после изготовления.

Это делает PPAL идеальным выбором для самых разных применений: от фасадов зданий и кровли до автомобильных панелей и промышленного оборудования..

Пошаговый процесс изготовления PPAL

Производство высококачественных алюминиевых листов с предварительно окрашенным покрытием требует точного проектирования и строгого контроля качества.. Вот подробный обзор ключевых этапов:

1. Подготовка алюминиевой подложки

Змеевики из высококачественного алюминия очищаются и обезжириваются для удаления масла., пыль, и примеси. Это обеспечивает идеальное прилегание слоев краски и гладкость поверхности., бездефектная поверхность.

2. Химическая обработка & Кондиционирование поверхности

Алюминиевая поверхность подвергается анодированию или конверсионному покрытию., улучшение коррозионной стойкости и создание слегка шероховатой текстуры, улучшающей адгезию краски..

…

Для получения более подробной информации о процессе производства алюминиевых листов с предварительно нанесенным покрытием, пожалуйста, нажмите, чтобы посетить: https://www.dw-al.com/a/news/manufacturing-process-of-pre-coated-aluminum-sheet.html