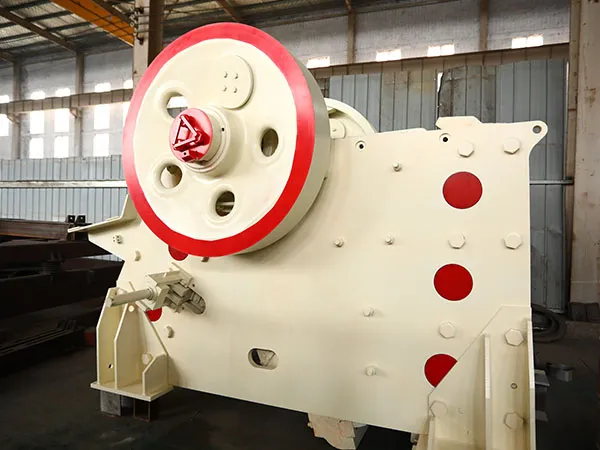

Диапазон частиц частиц челюсти зависит от дизайна и настроек конкретной машины и настроек. Обычно, а челюсть является основной дробилкой, это означает, что он используется для первого этапа уменьшения размера. Они могут справиться с очень большим материалом для подачи и производить грубый продукт. Выходной размер в основном определяется настройкой с закрытой стороной (CSS), минимальное расстояние между челюстями.

Диапазон размеров частиц в дробилках

Обычно, челюстные дробилки имеют коэффициент сокращения 6:1 Для 8:1, Это означает, что выходной размер составляет приблизительно от одной шестой до одного восьмого размера подачи. Для крупных промышленных дробилок челюсти, размер подачи может быть 1,000 миллиметровый, с диапазоном выходного размера 0 Для 200 миллиметровый. Лабораторные дремоты челюсти намного меньше, с размерами корма до 200 мм и финальные размеры такими же нормальными, как 1-6 миллиметровый.

Факторы, влияющие на размер частиц в дробилках челюсти

Несколько ключевых факторов влияют на конечный размер частиц и эффективность процесса дробления.

1. Дизайн и спецификации Jaw Crusher:

Размер дробилки: Большие дробилки челюсти обычно производят большие выходные частицы.

Дизайн челюсти: Профиль и материал челюстных тарелок (например, гофрированный, гладкий; плавный) Влияйте на раздавное действие и результирующий размер частиц.

Переверните настройку пластины (Закрытая сторона – CSS): Это самый важный фактор. CSS относится к минимальному зазору между фиксированной и подвижной челюстью на открытии разряда. Меньший CSS приводит к более тонкому выводу, в то время как более крупный CSS дает более крупный материал.

Угол от NIP: Угол, под которым материал “затопленный” между челюстями влияет на эффективность дробления и размер частиц.

Эксцентричный бросок: Расстояние, которое движущаяся челюсть, также играет роль в сокрушительном действии.

2. Свойства материала:

Твердость и абразивность: Сложные и более абразив, потенциально влияет на консистенцию частиц с течением времени.

Стойкость: Жесткие материалы сопротивляются переломам и могут потребовать больше проходов или более плотного CSS для достижения желаемого размера частиц.

Содержание влаги: Высокая влага может привести к тому, что материал держится вместе, приводя к засолу и непоследовательному размеру частиц.

Распределение размеров корма: Размер материала, подаваемого в дробилку (размер корма) непосредственно влияет на размер выходной частицы. Если корм слишком большой, это может быть не правильно раздавлено.

Форма корма: Нерегулярная форма корма может иногда привести к тому, чтобы соединить или противоречиво раздавливание.

3. Условия эксплуатации:

Скорость подачи: Перегрузка дробилки слишком высокой скоростью подачи может привести к снижению эффективности и получению более крупного продукта., так как материал не успевает как следует измельчиться.

…

Для получения более подробной информации о диапазоне размеров дробления щековой дробилки и факторах, влияющих на него., пожалуйста, нажмите здесь: https://www.yd-crusher.com/a/news/particle-size-range-of-jaw-crusher.html