Rodamientos de rodillos cruzados are precision bearings designed to handle radial, axial, y cargas de momento simultáneamente en una estructura compacta. Debido a su disposición única de rodillos cilíndricos orientados alternativamente en ángulo recto, Son ampliamente utilizados en robótica., Herramientas de máquina, Equipo medico, y mesas giratorias. La instalación correcta es fundamental para garantizar un rendimiento óptimo, larga vida útil, and high rotation accuracy. Installing crossed roller bearings requires precision and adherence to specific steps to ensure optimal performance and longevity. Here’s a general guide.

Cómo instalar rodamientos de rodillos cruzados

1. Preparación:

La limpieza es clave: Ensure the housing and shaft surfaces are meticulously clean and free from burrs, polvo, or any contaminants. Use a lint-free cloth and a suitable cleaning agent.

Inspeccionar componentes: Carefully inspect the bearing, eje, and housing for any damage, defectos, or irregularities.

Gather Tools: You’ll need a press, a heating device (induction heater or oil bath), appropriate mandrels or sleeves, a torque wrench, feeler gauges, and assembly lubricant.

2. Mounting the Inner Ring (si es aplicable):

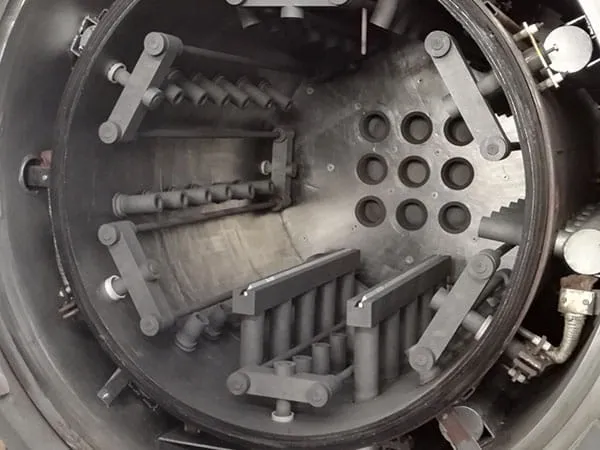

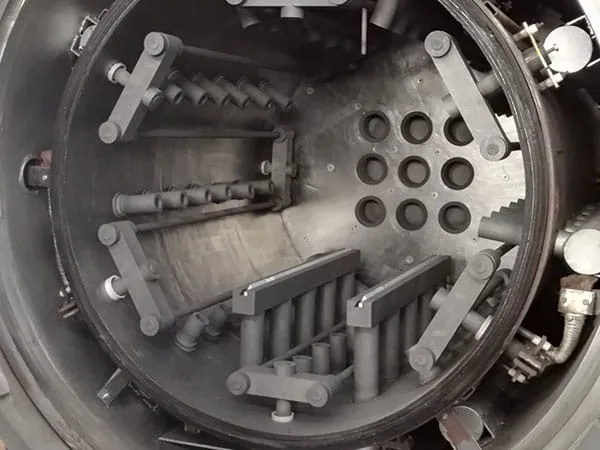

Calefacción (Recommended): For a proper interference fit, the inner ring of the bearing is often heated to expand it. An induction heater is ideal as it provides even heating. Alternativamente, an oil bath can be used, but ensure the oil is clean and heated to the recommended temperature (usually around 80-100°C / 176-212°F). Do not exceed 120°C (248°F) unless specified by the manufacturer.

DO NOT use an open flame.

Prensado (if not heated or for slight interference): If heating is not suitable or only a slight interference fit is required, a press can be used. Apply even pressure to the end face of the inner ring using a suitable mandrel or sleeve that contacts the entire inner ring face. Never press on the outer ring when mounting the inner ring.

Align and Slide: Once heated or pressed, carefully slide the inner ring onto the shaft, ensuring it’s properly aligned and seated against the shaft shoulder.

3. Mounting the Outer Ring:

Enfriamiento (si es aplicable): En algunos casos, the housing might be cooled to shrink it slightly before inserting the outer ring.

Prensado: Using a press, carefully press the outer ring into the housing bore. Ensure you apply even pressure to the end face of the outer ring using a suitable mandrel or sleeve that contacts the entire outer ring face. Never press on the inner ring when mounting the outer ring.

Alineación: Ensure the outer ring is perfectly aligned with the housing bore.

4. Assembling the Bearing into the Application:

Lubricación: Aplicar un delgado, even layer of the recommended lubricant (grease or oil) to the bearing races and rolling elements. This helps with initial rotation and prevents rust.

Careful Insertion: Gently insert the assembled bearing (or separate inner/outer rings if not pre-assembled) into its final position within the machine or mechanism.

…

For more detailed information on how to install cross roller bearings, por favor haga clic aquí: https://www.prsbearings.com/a/news/how-to-install-crossed-roller-bearings.html