Cribas vibratorias Son equipos esenciales en diversas industrias., incluida la minería, construcción, procesamiento químico, y agricultura, para separar materiales basados en el tamaño. Sin embargo, inherentemente generan vibraciones y ruido importantes, que puede conducir a:

Fatiga estructural y falla de la pantalla y estructuras de soporte.

Reducción de la eficiencia de detección y precisión.

Operador Moltura y riesgos para la salud (pérdida auditiva, problemas musculoesqueléticos).

Contaminación ambiental (molestia).

Por lo tanto, La vibración efectiva y la reducción de ruido es crucial para mejorar el rendimiento, fiabilidad, y seguridad de las pantallas vibratorias. Esto implica un enfoque multifacético que abarca:

1. Vibratoria de optimización de la dinámica de la pantalla:

Comprender y optimizar el comportamiento dinámico de la pantalla vibratoria es el primer paso para minimizar la vibración y el ruido no deseados.. Esto incluye:

Análisis modal: Identificar las frecuencias naturales y las formas de modo de la estructura de la pantalla. Evitar la operación cerca de las frecuencias resonantes es crítico. Esto implica tanto el modelado teórico (Análisis de elementos finitos - FEA) y análisis modal experimental.

Análisis de fuerza: Determinar con precisión las fuerzas emocionantes generadas por el mecanismo vibratorio (p.ej., pesas excéntricas, vibradores electromagnéticos).

Análisis cinemático: Estudiar el movimiento de la cubierta de pantalla y el flujo de material para optimizar los parámetros de detección (amplitud, frecuencia, ángulo de carrera).

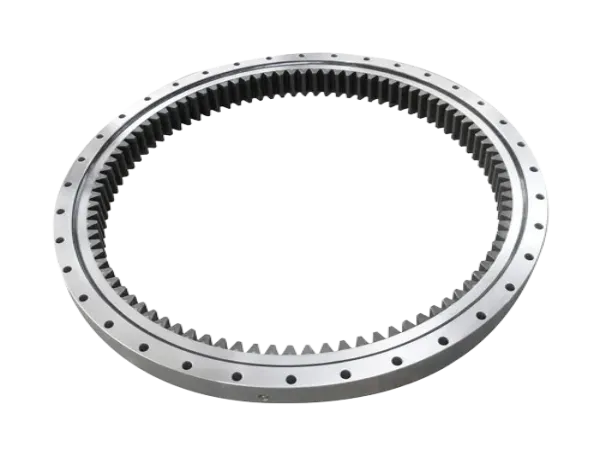

Equilibrio de masa: Equilibrar adecuadamente las masas giratorias u oscilantes para minimizar las fuerzas desequilibradas que contribuyen a la vibración. Esto incluye el equilibrio dinámico de los vibradores excéntricos.

Mojadura: Introducir la amortiguación para disipar la energía y reducir las amplitudes de vibración. Esto se puede lograr a través de:

Selección de materiales: Elegir materiales con propiedades de amortiguación inherentes.

Amortiguadores viscoelásticos: Aplicar materiales viscoelásticos a áreas críticas para absorber la energía de vibración.

Amortiguadores de fricción: Utilización de interfaces de fricción para disipar la energía a través del movimiento relativo.

Optimización de parámetros de excitación: Ajuste de la frecuencia, amplitud, y ángulo de carrera para minimizar la vibración mientras se mantiene una eficiencia de detección óptima.

Optimización estructural: Modificación de la estructura de la pantalla para aumentar la rigidez y alejar las frecuencias naturales de las frecuencias operativas. Esto podría implicar cambios en el grosor del material., nervaduras, o agregar soportes.

Optimización del flujo de material: Asegurar una distribución uniforme de material en la cubierta de la pantalla para evitar la carga desigual y los desequilibrios dinámicos.

2. Aplicación de nuevas tecnologías de reducción de vibraciones:

Se pueden implementar varias tecnologías avanzadas para mitigar aún más la vibración y el ruido:

Control de vibración activo (AVC):

Utiliza sensores para detectar vibraciones y actuadores para generar fuerzas opuestas, cancelando efectivamente la vibración no deseada.

Complejo y costoso pero altamente efectivo para la reducción de vibración dirigida.

…

Para obtener información más detallada sobre la reducción de la vibración de la pantalla de vibración y la reducción de ruido, por favor haga clic aquí: https://www.hsd-industry.com/news/vibrating-screen-vibration-and-noise-reduction/