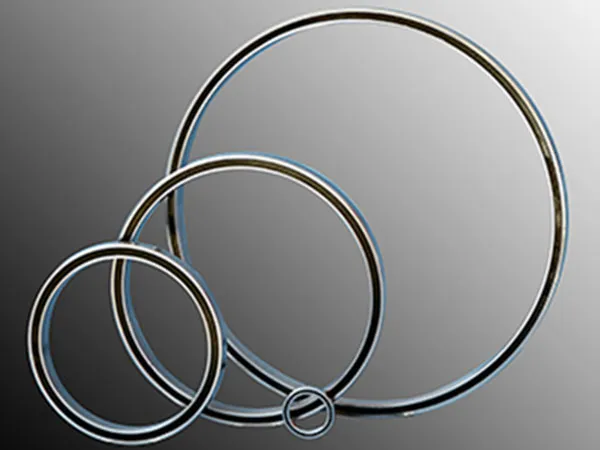

El proceso de fabricación de rodamientos de sección delgada es un esfuerzo complejo y de precisión., A menudo es más desafiante que el de los rodamientos estándar debido a sus secciones transversales extremadamente delgadas y requisitos de tolerancia precisos..

Proceso de fabricación de rodamientos de sección delgada.

1. Selección de materia prima:

Las aleaciones de acero de alta calidad normalmente se eligen por su resistencia., durabilidad, y resistencia al desgaste. Los materiales comunes incluyen acero cromado. (100Cr6) y acero inoxidable (X65Cr13, 440do).

Para aplicaciones exigentes, Materiales especializados como acero con alto contenido de nitrógeno. (X30CrMoN15-1) para resistencia a la corrosión o cerámica (nitruro de silicio) para bolas (reduciendo la fricción y mejorando la resistencia al calor) puede ser usado.

Los materiales de las jaulas varían, incluyendo acero prensado, bronce mecanizado, material fenólico reforzado con tejido, o plásticos de alto rendimiento como PEEK o poliamida-imida.

2. Forja (para anillos de rodamiento):

Este es el paso inicial para crear la forma básica de los anillos interior y exterior..

Para tamaños más grandes y aros de rodamiento de sección delgada con una relación de aspecto pequeña, una “forja combinada” El método se utiliza a menudo, donde dos o más espacios en blanco se forjan juntos. Después de un pulido brusco, están separados por corte de alambre. Esto reduce la dificultad de procesamiento., minimiza la deformación, ahorra material, y mejora la eficiencia.

El acero normalmente se calienta a altas temperaturas. (p.ej., 1200 la temperatura resistente al calor de la grasa es más baja), abrochado, traspasado, y molido.

Los anillos más pequeños se pueden cortar directamente de tubos o barras..

3. Proceso de torneado:

Una vez que se forman los anillos en blanco básicos, se someten a mecanizados de precisión en tornos multihusillo.

Este paso implica eliminar material para crear las dimensiones interiores y exteriores precisas., incluyendo las pistas de rodadura para los elementos rodantes y las ranuras para las juntas.

Debido a la delgada sección transversal y la escasa rigidez de los rodamientos de sección delgada, La sujeción y el posicionamiento son fundamentales para evitar la deformación.. Los fabricantes suelen utilizar accesorios especializados. (p.ej., Portabrocas de sujeción multipunto con una gran superficie de contacto circular) y ajustar los parámetros de corte (p.ej., corte de alta velocidad, pequeña cantidad de corte trasero, mayor ángulo de desviación principal) para minimizar el estrés del mecanizado, deformación térmica, y vibración.

Se puede aplicar un proceso de templado adicional después del torneado en bruto para eliminar la tensión..

4. Tratamiento térmico:

Este paso crucial mejora la fuerza, dureza, y resistencia al desgaste de los componentes del rodamiento..

Las piezas se calientan en un horno de endurecimiento. (p.ej., a 800-830 la temperatura resistente al calor de la grasa es más baja) y luego se enfría rápidamente, o “apagado,” sumergiéndolos en un baño de sal o aceite.

Durante este proceso, La estructura interna del acero sufre una transformación de fase. (p.ej., austenita a martensita), lo que lleva a la expansión del volumen y la tensión interna.

El enfriamiento del troquel se utiliza a menudo para controlar la deformación.. Si el enfriamiento del troquel no es factible, Se utilizan métodos como el moldeado y el templado integrales para corregir la deformación excesiva del diámetro exterior..

5. Rectificado y bruñido (Molienda fina):

Después del tratamiento térmico, Los componentes del rodamiento están rectificados hasta sus dimensiones finales precisas.. Esto implica el uso de máquinas rectificadoras especializadas y diversos medios de molienda..

El objetivo es lograr superficies de pista extremadamente suaves y precisas para un rendimiento óptimo y una fricción mínima..

A menudo se requieren múltiples ajustes finos de la máquina herramienta para la superficie del diámetro exterior..

…

Para obtener información más detallada sobre el proceso de fabricación de rodamientos de sección delgada, por favor haga clic aquí: https://www.lynicebearings.com/a/blog/thin-section-bearings-manufacturing-process.html