El acero y el hormigón son los dos materiales más habituales en la construcción a gran escala, pero tienen diferencias clave en las propiedades, métodos de construcción, costo, e impacto ambiental. En general, estructuras de acero son conocidos por su alta relación resistencia-peso, que permite aligerar, diseños más flexibles y construcción más rápida, mientras que las estructuras de hormigón se valoran por su alta resistencia a la compresión, durabilidad, y resistencia al fuego.

Diferencias entre estructura de acero y estructura de hormigón

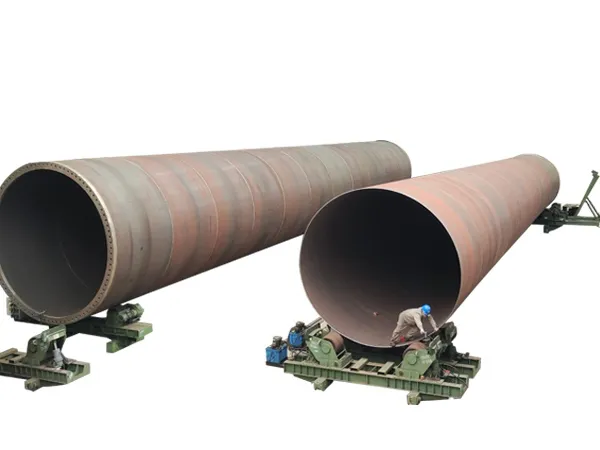

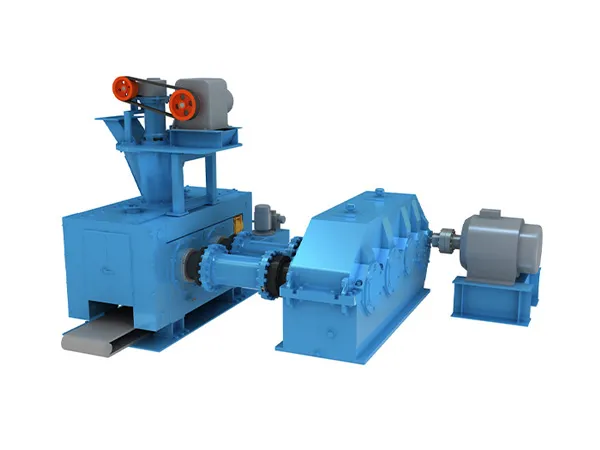

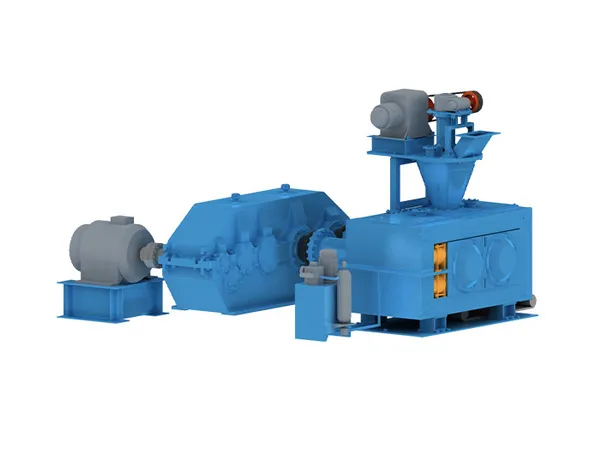

Estructura de acero

Descripción: Las estructuras de acero están hechas de componentes de acero interconectados., como vigas, columnas, y cerchas, que se fabrican en un taller y luego se ensamblan en el sitio mediante pernos o soldadura.

ventajas:

Alta relación resistencia a peso: El acero es increíblemente fuerte para su peso., permitiendo estructuras más ligeras y luces más largas sin soportes intermedios.

Velocidad de construcción: La fabricación fuera del sitio y el montaje rápido en el sitio reducen significativamente el tiempo de construcción..

Durabilidad: El acero es un material duradero., resistente a la putrefacción, insectos, y envejecimiento.

Flexibilidad y adaptabilidad: Las estructuras de acero se pueden modificar fácilmente, expandido, o incluso desmontado y reutilizado.

Resistencia sísmica: La ductilidad del acero le permite deformarse bajo tensión sin fallar por fragilidad., haciéndolo bueno para áreas propensas a terremotos.

Sostenibilidad: El acero es 100% reciclable, convirtiéndolo en una opción amigable con el medio ambiente.

desventajas:

Corrosión: El acero es susceptible a oxidarse cuando se expone a la humedad y al oxígeno., que requieren recubrimientos protectores o mantenimiento regular.

Resistencia al fuego: Mientras el acero no arde, su resistencia puede disminuir significativamente a altas temperaturas, conduciendo al colapso estructural. Las medidas ignífugas son esenciales.

Costo: El costo inicial de los materiales de acero y la fabricación puede ser más alto que el concreto.

Fatiga: Bajo carga cíclica repetida, El acero puede experimentar la falla de la fatiga.

Aplicaciones típicas: Edificios de gran altura, puentes, edificios industriales, estadios, techos de larga distancia, y estructuras expuestas estéticamente.

Estructura de concreto

…

Se puede encontrar información más detallada sobre la diferencia entre la estructura del acero y la estructura de concreto.: https://www.meichensteel.com/a/news/differences-between-steel-structure-and-concrete-structure.html