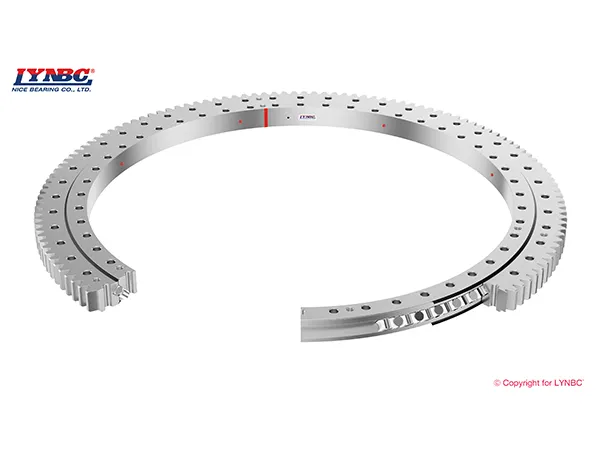

Cojinetes de giro play a crucial role in heavy machinery, equipo de construcción, turbinas de viento, sistemas de manipulación de materiales, y diversas aplicaciones industriales. Como componente central de soporte rotacional, su durabilidad impacta directamente en la estabilidad del equipo, eficiencia operativa, y costos de mantenimiento a largo plazo.

Por lo tanto, Una de las principales preocupaciones de muchas empresas antes de comprar rodamientos giratorios es su vida útil..

This article will provide a comprehensive analysis of the typical service life of slewing bearings from a professional perspective, highlighting the key factors influencing their lifespan and offering practical maintenance recommendations to help companies effectively extend equipment lifespan.

Typical Service Life of Slewing Bearings

Under standard working conditions and with proper maintenance, a high-quality slewing bearing typically offers a service life ranging from 50,000 a 100,000 horas.

Sin embargo, actual service life is often shortened by load variations, improper lubrication, installation problems, or harsh operating conditions.

Understanding a bearing’s true lifespan helps businesses:

Develop reasonable maintenance and replacement plans

Prevent equipment downtime due to bearing failure

Match more suitable models and structural designs during procurement

Main Factors That Affect Slewing Bearing Life

1. Condiciones de carga

Load is the primary factor affecting the lifespan of a slewing bearing.

When a bearing is subjected to its rated load, its lifespan is usually maintained within its design range. Sin embargo, si:

Prolonged overload

Frequent impact loads

Unbalanced load distribution

All of these will accelerate the wear of the raceways and rolling elements, causing fatigue spalling and ultimately leading to premature failure.

Recomendación: Accurately calculate the overturning moment, carga axial, and radial load during the selection phase to ensure a sufficient safety factor.

…

For more detailed information on the service life and influencing factors of slewing bearings, por favor haga clic para visitar:https://www.lynicebearings.com/a/blog/slewing-bearing-service-life-and-influencing-factors.html