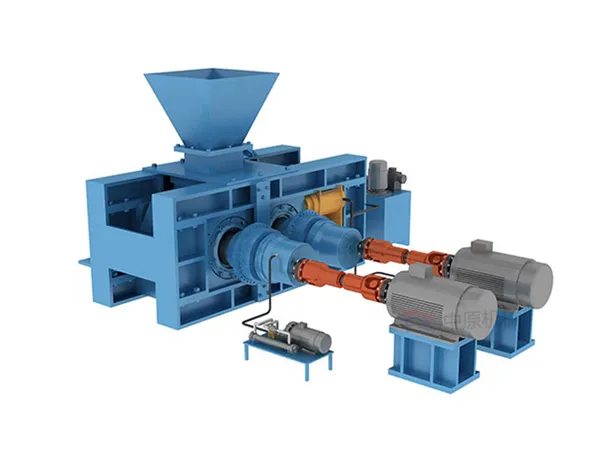

Vibrating feeders are devices used to feed bulk materials continuously and uniformly to processing machines or conveyors. Son ampliamente utilizados en industrias como la minería., metalurgia, carbón, construcción, máquina de hacer briquetas de carbón, y procesamiento de alimentos. The specifications and models of vibrating feeders vary depending on the application, material to be handled, and desired capacity.

Specifications of Vibrating Feeders

Capacidad:

The capacity of vibrating feeders ranges from a few tons per hour (tph) to several hundred tph. Common capacities include 10, 50, 100, 200, y 500 tph, depending on the model and application.

Size of the Feeder Deck:

The width and length of the feeder deck can vary. Typical widths range from 300 mm a 3,000 mm, and lengths range from 600 mm a 6,000 mm.

Feeder Type:

Electromagnetic Vibrating Feeders: Ideal for smaller volumes and precise feeding applications.

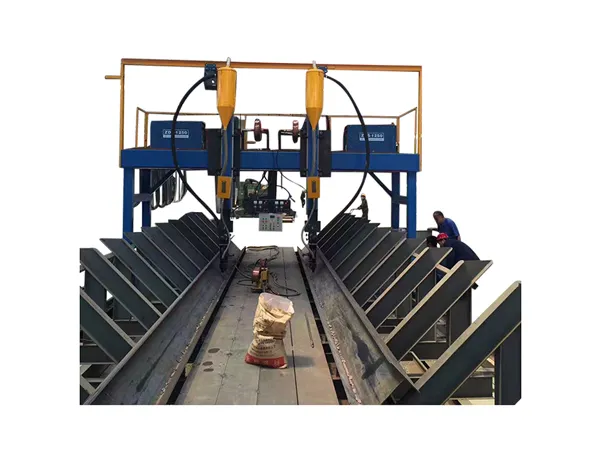

Electromechanical Vibrating Feeders: Suitable for handling larger loads and for heavy-duty applications.

Grizzly Vibrating Feeders: These feeders have grizzly bars for separating fines and are used for handling materials with large lump sizes.

Frecuencia y amplitud de vibración:

Frequency usually ranges from 750 a 3000 vibraciones por minuto.

Amplitude varies from 1 mm a 15 mm, depending on the material flow and feeder design.

Motor Power:

Motor power ranges from 0.5 kW to 15 kW or more, depending on the feeder size and capacity.

Material of Construction:

Made from various materials, such as carbon steel, acero inoxidable, and high-strength alloys, depending on the application and material to be handled.

Installation Type:

Available in stationary, mobile, or portable configurations depending on the setup and use.

…

For more detailed information on the specifications and models of vibrating feeders, por favor haga clic aquí: https://www.zexciter.com/en/a/news/vibrating-feeder-specifications-and-models.html