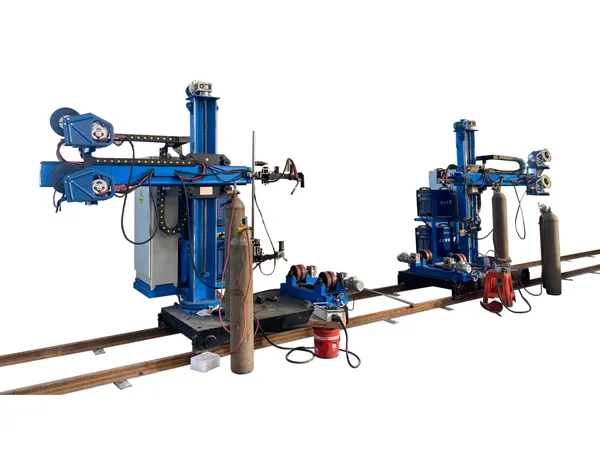

UNA rotador de soldadura de tornillo de avance Es un equipo especializado que se utiliza en procesos de soldadura para soportar y rotar piezas de trabajo cilíndricas., como tuberías, tanques, o recipientes a presión, durante la soldadura. El uso de un mecanismo de tornillo de avance permite un ajuste preciso de la posición y alineación de la pieza de trabajo..

Funciones del rotador de soldadura de tornillo guía

1. Soporte y estabilidad de piezas de trabajo:

La función principal de un rotador de soldadura de tornillo de avance es proporcionar un soporte estable para piezas de trabajo cilíndricas durante la soldadura.. Los rodillos del rotador sostienen la pieza de trabajo., evitando que se mueva o vibre, lo que asegura una soldadura consistente.

2. Rotación controlada:

El rotador permite la rotación controlada de la pieza de trabajo.. Esta rotación se puede ajustar a la velocidad deseada., Lo cual es crucial para lograr una soldadura uniforme alrededor de la circunferencia de la pieza de trabajo.. La velocidad de rotación se puede ajustar según los requisitos de soldadura..

3. Posicionamiento y alineación precisos:

El mecanismo de tornillo de avance permite un posicionamiento y alineación precisos de la pieza de trabajo.. Ajustando el tornillo de avance, Los operadores pueden mover la pieza de trabajo horizontalmente a lo largo del eje., asegurándose de que esté correctamente alineado para soldar. Esto es especialmente importante para mantener la distancia correcta entre el soplete y la pieza de trabajo..

4. Distancia de rodillo ajustable:

El rotador de soldadura de tornillo de avance generalmente permite el ajuste de la distancia del rodillo para acomodar piezas de trabajo de varios diámetros.. El mecanismo de tornillo de avance facilita cambiar el espacio entre los rodillos para adaptarse al tamaño específico del objeto cilíndrico que se está soldando..

5. Facilitando la soldadura continua:

Girando la pieza de trabajo a una velocidad constante, el rotador permite soldar continuamente alrededor de toda la circunferencia sin detenerse. Este movimiento continuo ayuda a producir una soldadura más uniforme y más fuerte..

6. Reducir la fatiga del operador:

El rotador reduce la necesidad de manipulación manual y reposicionamiento de la pieza de trabajo., lo que disminuye la fatiga del operador y aumenta la seguridad. Los operadores pueden centrarse más en el proceso de soldadura que en el manejo físico de la pieza de trabajo..

…

Puede encontrar información más detallada sobre las funciones del rotador de soldadura de tornillo de avance en: https://www.bota-weld.com/en/a/news/lead-screw-welding-rotator-functions.html