Firstly, the sand treatment system is greatly simplified, the molding sand can be completely reused, and the sand falling is easy, which greatly reduces the workload and labor intensity of the falling sand.

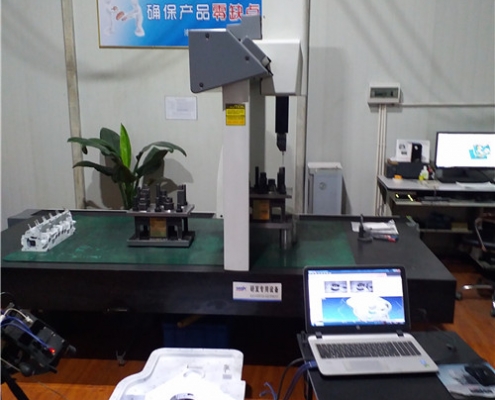

Secondly, it is easy to realize mechanized automatic assembly line production, and the production line has great elasticity, and can realize the production of different alloys, castings of different shapes and sizes on one production line. Reduced dust, smoke and noise pollution, greatly improved the labor environment of foundry workers, reduced labor intensity, the industry dominated by male workers can become an industry dominated by women workers.

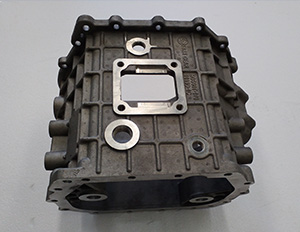

The shape of the part is not limited by the traditional casting process, freeing the mechanical design worker to freely design the optimal casting shape based on the performance of the part.