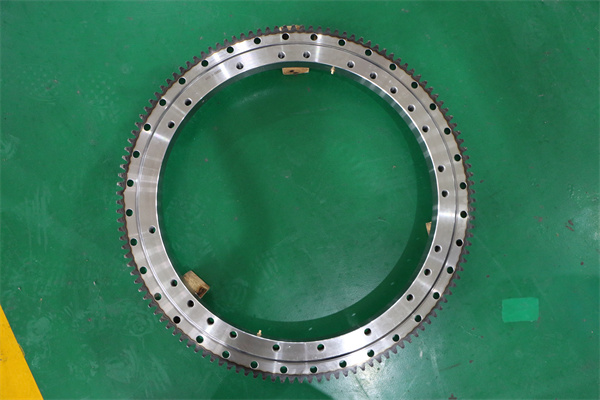

Replacing the slewing bearing on an excavator is an important maintenance task that helps to ensure the safety and reliability of the equipment. It is important to follow the manufacturer’s recommendations for replacement intervals and to have the work performed by a qualified technician with experience in heavy equipment maintenance and repair.

There are several reasons why the slewing bearing on an excavator may need to be replaced. Here are some of the most common:

Úsese y tírese: Tiempo extraordinario, the slewing bearing may wear out due to the constant movement and weight that it is subjected to. This can cause the bearing to become loose or develop play, which can affect the stability and performance of the excavator.

Damage: The slewing bearing can also become damaged due to external factors such as impact or exposure to harsh environments. If the bearing is cracked or otherwise compromised, it may need to be replaced to prevent further damage or failure.

Corrosión: If the excavator is used in environments where it is exposed to saltwater or other corrosive substances, the slewing bearing may become corroded and damaged over time. This can affect the integrity and functionality of the bearing, requiring replacement.

Mantenimiento: En algunos casos, the slewing bearing may need to be replaced as part of a regular maintenance schedule. Esto se hace para evitar que se desarrollen posibles problemas y para garantizar que la excavadora continúe funcionando sin problemas y de manera eficiente..

Reemplazar el cojinete de giro en una excavadora puede ser una tarea compleja y requiere una planificación y ejecución cuidadosas. Estos son los pasos generales involucrados:

…

Para obtener información más detallada sobre la sustitución de los cojinetes de giro de la excavadora, por favor haga clic para visitar:https://www.excavatorbearing.com/a/bearing-knowledge/excavator-slewing-bearing-replacement-process.html