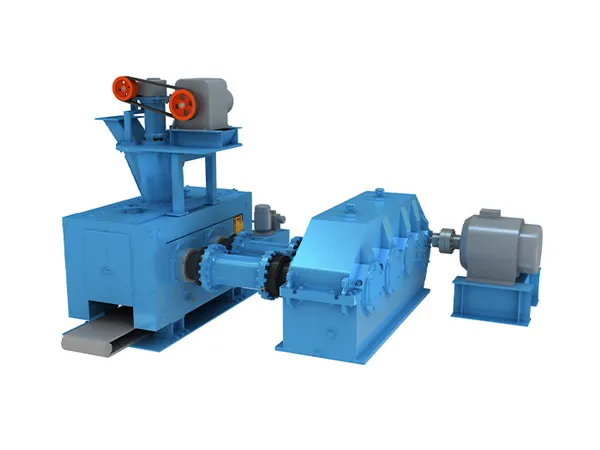

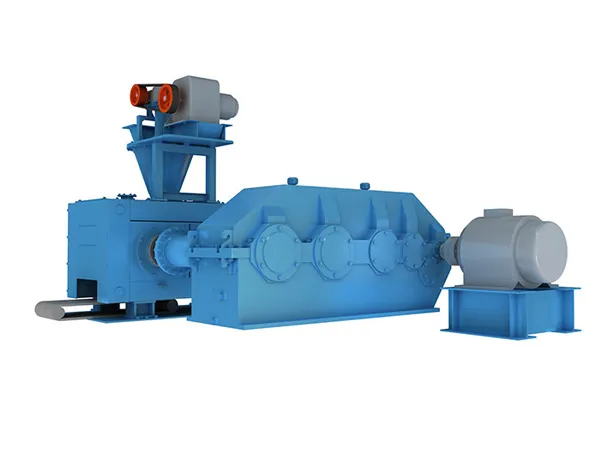

UNA prensa de briquetas, también conocida como prensa de briquetas o máquina de briquetas, es un dispositivo utilizado para convertir varios tipos de biomasa, metal, u otros materiales en uniforme, briquetas en forma. Estas briquetas suelen tener forma cilíndrica y pueden variar de tamaño según los requisitos específicos de la aplicación..

¿Cómo funciona la prensa briquetadora?

Alimentación de materiales: El material crudo, which could be biomass (such as wood chips, serrín, or agricultural residues), virutas de metal, or other types of material, is fed into the briquetting press. This can be done manually or through automated feeding systems, depending on the scale and complexity of the operation.

Cámara de compresión: Inside the briquetting press, there is a compression chamber where the raw material is compacted under high pressure. This pressure is applied using a hydraulic system, mechanical system, O una combinación de ambos.

Compression and Briquette Formation: As the raw material enters the compression chamber, it is subjected to high pressure, which compresses it into a dense mass. The pressure forces the material to bind together, forming briquettes of the desired shape and size. The shape of the briquettes can vary depending on the design of the press and any additional shaping attachments.

Ejection or Discharge: Una vez formadas las briquetas, they are ejected from the press either manually or through automated ejection systems. En algunos casos, the briquettes may need to be cooled or cured before they are ready for use or further processing.

…

More detailed information about how the briquetting machine works can be found here:https://www.zymining.com/en/a/news/how-does-briquetting-press-work.html