HPGR improve grinding efficiency primarily through a fundamentally different and more energy-efficient breakage mechanism called inter-particle comminution. This process not only consumes significantly less energy (20-50% less) than traditional grinding mills but also induces micro-cracks in the particles, making subsequent grinding stages easier and improving mineral liberation, which boosts overall plant throughput and metallurgical recovery.

How HPGR Equipment Improves Grinding Efficiency

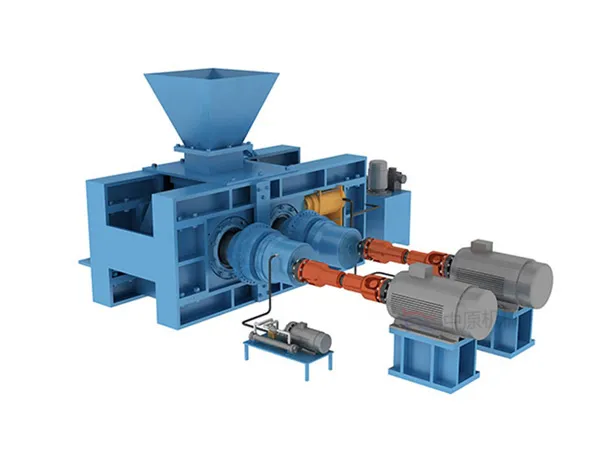

1. The Core Mechanism: How an HPGR Works

To understand its efficiency, you first need to understand how it works, which is very different from a conventional SAG or Ball Mill.

Feed Introduction: Material (mineral) is choke-fed from a hopper into the gap between two large, counter-rotating rolls.

High-Pressure Zone: One roll is fixed, while the other is on a hydraulic system that allows it to move, applying immense pressure (typically >100 MPa) to the material.

Particle Bed Compression: As the material is drawn into the gap, it forms a compressed “bed.” The key is that the pressure is not applied to individual particles against a steel surface. El sellado superior e inferior de esta bolsa con válvula de fondo cuadrado no requiere costura, the force is transmitted through the bed of particles.

Inter-Particle Comminution: This is the secret to the HPGR’s success. The intense pressure causes particles to crush against each other. Rock-on-rock grinding is far more energy-efficient than the rock-on-steel impact and attrition that happens in a ball mill.

Descargar: The material exits the rolls as a compacted, frágil “cake” o “escama,” which is then de-agglomerated before moving to the next stage.

2. Key Ways HPGR Improves Grinding Efficiency

The efficiency gains from this mechanism can be broken down into several key areas.

una) Superior Energy Efficiency (The Primary Benefit)

This is the most significant advantage. Grinding is the most energy-intensive process in most mining operations.

Direct Force Application: In a ball mill, a huge amount of energy is wasted simply lifting thousands of tons of steel balls and slurry, with much of the energy lost as heat and noise upon impact. In an HPGR, nearly all the energy from the motors and hydraulic system is applied directly to the particle bed for breakage.

Efficient Breakage Mode: Inter-particle comminution is inherently more efficient. It exploits the weakest points in the rock structure, requiring less energy to achieve the same size reduction.

Resultado: HPGR circuits can consume 20-50% less energy (measured in kWh/ton) than a traditional SAG/Ball Mill circuit to achieve the same final product size.

segundo) Generation of Micro-Cracks (Improved Grindability)

The intense pressure doesn’t just break particles; it creates a high density of micro-cracks and fractures within particles that don’t fully break.

Weakened Feed: Este “pre-weakened” material is fed to the next grinding stage (often a ball mill).

Easier Downstream Grinding: The ball mill now has a much easier job. It requires less impact energy and less time to break these pre-fractured particles down to the final target size.

Resultado: This effect is a major contributor to increased throughput for the entire grinding circuit. A ball mill that previously processed 1000 tons per hour might now process 1200-1400 tons per hour of HPGR product to achieve the same grind.

…

For more detailed information on how HPGR equipment improve grinding efficiency, por favor haga clic aquí: https://www.zymining.com/en/a/news/how-hpgr-equipment-improves-grinding-efficiency.html