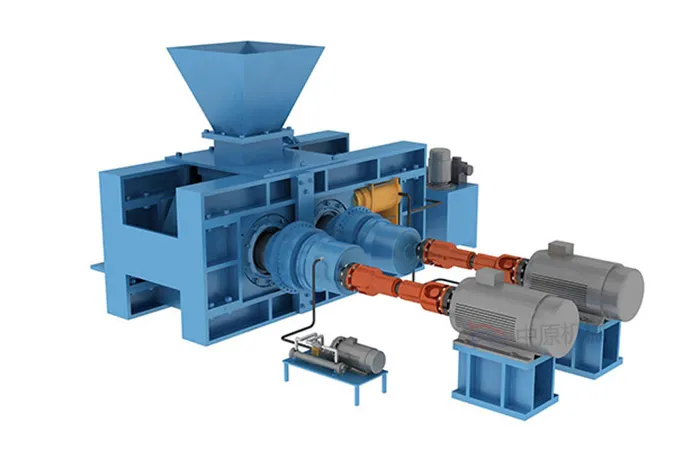

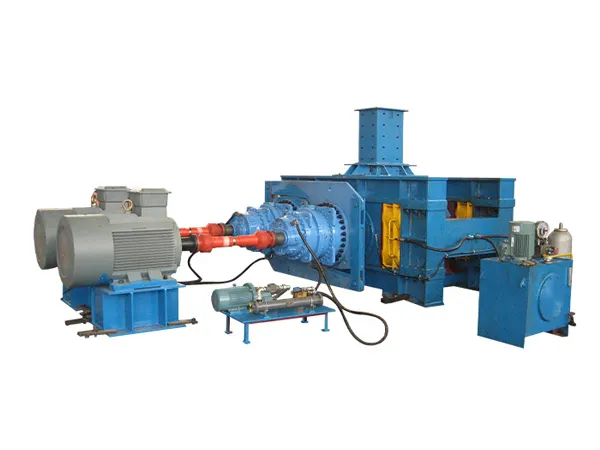

Rodillos de molienda de alta presión (HPGR), core grinding equipment in industries such as cement, minería, and metallurgy, are critical components that bear immense pressure. Sin embargo, under long-term, high-load operation, HPGR roller surface wear is an unavoidable problem. Wear not only reduces production efficiency and increases energy consumption, but can also cause downtime and significant economic losses. Effective and cost-effective roller surface repair has become a key concern within the industry.

This article provides an in-depth analysis of HPGR roller surface repair technologies, helping you select the most appropriate solution to extend equipment life and improve production efficiency.

Understanding Roller Surface Wear: Why Repair Is Necessary?

During operation, materials in a HPGR are subjected to intense compression and shearing between two counter-rotating rollers. This constant friction and impact gradually develops pits, grooves, and cracks on the roller surface. If not addressed promptly, wear will worsen, affecting material pulverization efficiency and potentially leading to roller surface spalling and serious damage to the equipment.

Roller surface repair is more than just a simple “patch.” It involves restoring the roller surface’s original dimensions and wear-resistant properties through specialized processes and wear-resistant materials, enabling continued efficient and stable operation.

High-Pressure Grinding Roll Surface Repair Technology Revealed

Corrientemente, the mainstream high-pressure grinding roller (HPGR) roller surface repair technologies on the market are the following:

1. Hardfacing Repair: Precise, Durable, and Economical

Hardfacing repair is the most widely used and proven roller surface repair method. Using a heat source such as an arc or plasma, specially formulated wear-resistant alloy wire or powder is deposited onto the worn roller surface, forming a new, highly wear-resistant layer.

Technical Advantages:

High Wear Resistance: Using HPGR wear-resistant materials such as high-chromium cast iron and high-carbon, high-alloy steel, the repaired roller surface exhibits high hardness and wear resistance, extending its service life far beyond the original roller surface.

…

For more detailed information on high pressure grinding roller surface repair technology, por favor haga clic aquí: https://www.zymining.com/en/a/news/high-pressure-grinding-rolls-surface-repair-technology.html