En la industria de trituración de piedra, La trituradora de mandíbulas desempeña un papel insustituible.. Para muchas plantas de arena y grava., mejorar la capacidad general, reduciendo el consumo de energía, y lograr un tamaño de partícula estable del producto terminado dependen de la optimización del rendimiento de la trituradora de mandíbulas y la mejora de las estrategias de uso.. This article will break down how trituradores de la mandíbula help stone crushing plants significantly improve efficiency, from working principles and efficiency determinants to real-world application cases and solutions to common problems.

El papel principal de la trituradora de mandíbulas en las plantas trituradoras de piedra

Las trituradoras de mandíbulas se utilizan principalmente en la etapa de trituración primaria del proceso de trituración de piedra., comprimir grandes trozos de mineral o piedra en tamaños de partículas pequeñas a medianas adecuadas para su posterior trituración secundaria.

● Brief Description of Working Principle

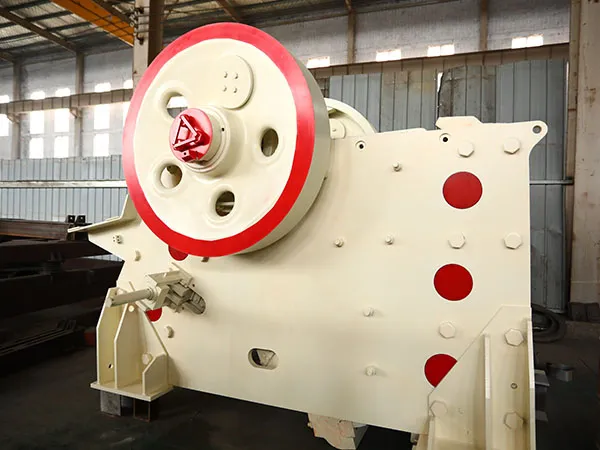

La trituradora de mandíbulas tritura gradualmente grandes trozos de material mediante la compresión y compresión repetidas entre la placa de mandíbula fija y la placa de mandíbula móvil.. El motor acciona la polea y el eje excéntrico., haciendo que la mandíbula móvil se acerque y se aleje periódicamente de la mandíbula fija, completando así el proceso de trituración continua.

● Importance of Primary Crushing

La eficiencia de la trituración primaria determina directamente el rendimiento y la estabilidad de toda la línea de producción..

Cuanto más estable sea el tamaño de las partículas trituradas, mayor será la eficiencia de los equipos posteriores (trituradora de impacto, trituradora de cono, maquina para fabricar arena);

Jaw crushers can stabilize stone flow, mejorar la eficiencia de trituración, y reducir el riesgo de bloqueo;

Con su gran índice de trituración y bajo costo operativo, Es el equipo de trituración primaria preferido para la mayoría de las plantas de arena y grava..

Factores clave para mejorar la eficiencia de la trituradora de mandíbulas

La producción y la eficiencia operativa de una trituradora de mandíbulas se ven afectadas por una variedad de factores.. The following are the four most crucial aspects.

1. High Crushing Ratio and Large Processing Capacity

Highly Efficient Working Principle: Jaw crushers crush materials using compression, splitting, and bending methods. The material is repeatedly compressed between the moving and fixed jaws, achieving highly efficient crushing.

Ideal Choice for Primary Crushing: Jaw crushers are typically used as the first step in a crushing production line (primary crushing). They can handle large-particle-size, high-hardness materials, directly crushing large ore or rocks to medium particle size, providing suitable feed size for subsequent secondary and tertiary crushing processes (such as cone crushers and impact crushers), thereby reducing the load on subsequent equipment.

Continuous Production: Modern jaw crushers are designed with large feed openings and deep cavities, ensuring smooth material entry and crushing, guaranteeing the continuity and stability of the production line.

2. Structural Design Optimizes Production Efficiency

Adjustable Discharge Opening: By adjusting the discharge opening size, the particle size range of the product can be flexibly controlled to meet the requirements of different customers or subsequent processes. Precise particle size control helps reduce over-crushing, improving finished product quality and efficiency.

Streamlined Process: Some large jaw crushers can directly crush large stones to near the final product particle size, reducing the number of crushing stages and thus simplifying the entire crushing process.

Easy Replacement of Wear Parts: Wear parts such as jaw plates are designed for quick replacement, shortening maintenance and downtime and improving the actual operating efficiency of the equipment.

…

For more detailed information on how jaw crushers can improve the efficiency of modern stone crushing plants, por favor haga clic para visitar: https://www.yd-crusher.com/a/news/how-to-improve-the-crushing-efficiency-of-a-jaw-crusher.html