Jaw crushers are widely used in industries such as mining, producción agregada, y reciclaje de residuos de construcción debido a su estructura robusta, alta eficiencia de trituración, y amplia adaptabilidad. Sin embargo, Seleccionar el modelo correcto para diferentes durezas de materiales., contenido de humedad, tamaño de partícula, y los requisitos de salida no son fáciles. This article provides a practical and systematic jaw crusher selection guide to help you avoid selection errors, improve production efficiency, and reduce operating costs.

Jaw Crusher Basics

1. Common Models and Features

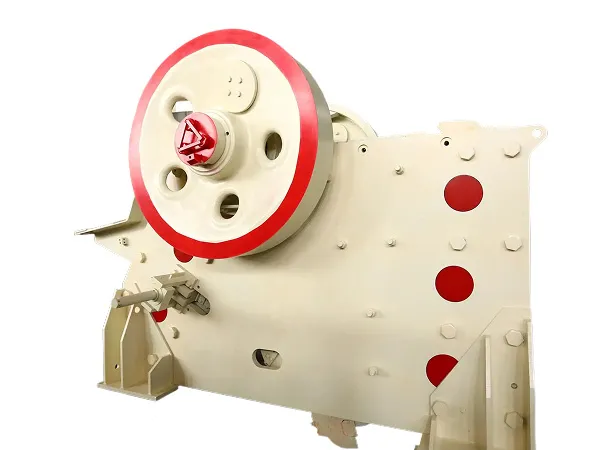

Stationary Jaw Crusher: Suitable for long-term fixed sites such as mines and aggregate plants, offering high output and stable operation.

Mobile Jaw Crusher: Equipped with a tracked or wheeled chassis, allowing for flexible movement and suitable for construction waste processing or multi-site construction.

Single Toggle Jaw Crusher: High crushing efficiency, estructura simple, and low maintenance cost.

Double Toggle Jaw Crusher: Uniform force distribution in the crushing chamber, suitable for ultra-hard materials, stable operation but more complex maintenance.

2. Working Principle and Applicable Scenarios

Jaw crushers use the periodic compression of fixed and movable jaw plates to crush large pieces of ore into the required particle size. Main applications include:

Coarse crushing of raw ore

Crushing of construction waste

Materials with compressive strength ≤320MPa, such as various ores, caliza, and granite.

Select the jaw crusher based on the material characteristics.

…

For more detailed information on jaw crusher selection guidelines, por favor haga clic para visitar: https://www.yd-crusher.com/a/news/jaw-crusher-selection-guide.html