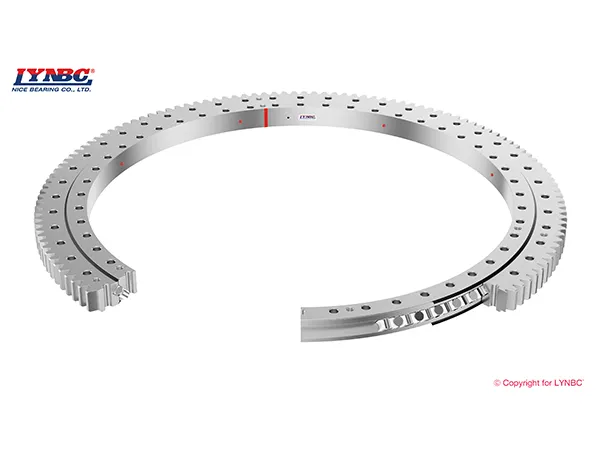

Поворотные подшипники играют решающую роль в тяжелом машиностроении, Строительное оборудование, ветряные турбины, системы транспортировки материалов, и различные промышленные применения. В качестве основного компонента поддержки ротации, их долговечность напрямую влияет на устойчивость оборудования, операционная эффективность, и долгосрочные затраты на техническое обслуживание.

Поэтому, Основной проблемой для многих компаний перед покупкой поворотных подшипников является срок их службы..

В этой статье будет представлен всесторонний анализ типичного срока службы поворотных подшипников с профессиональной точки зрения., выделение ключевых факторов, влияющих на срок их службы, и предложение практических рекомендаций по техническому обслуживанию, которые помогут компаниям эффективно продлить срок службы оборудования..

Типичный срок службы поворотных подшипников

При стандартных условиях работы и при правильном обслуживании., высококачественный поворотный подшипник обычно имеет срок службы от 50,000 Для 100,000 часов.

Однако, Фактический срок службы часто сокращается из-за изменений нагрузки, неправильная смазка, проблемы с установкой, или суровые условия эксплуатации.

Понимание истинного срока службы подшипника помогает бизнесу:

Разработайте разумные планы технического обслуживания и замены.

Предотвращение простоев оборудования из-за выхода из строя подшипников

Сопоставление более подходящих моделей и структурных конструкций во время закупок

Основные факторы, влияющие на срок службы поворотного подшипника

1. Условия нагрузки

Нагрузка является основным фактором, влияющим на срок службы поворотного подшипника..

Когда подшипник подвергается номинальной нагрузке, срок его службы обычно поддерживается в пределах расчетного диапазона. Однако, если:

Длительная перегрузка

Частые ударные нагрузки

Несбалансированное распределение нагрузки

Все это ускорит износ дорожек качения и тел качения., вызывая усталостное растрескивание и в конечном итоге приводящее к преждевременному выходу из строя.

Рекомендация: Точно рассчитать опрокидывающий момент, осевая нагрузка, и радиальная нагрузка на этапе выбора, чтобы обеспечить достаточный запас прочности.

…

Более подробную информацию о сроке службы и влияющих факторах опорно-поворотных устройств см., пожалуйста, нажмите, чтобы посетить:https://www.lynicebearings.com/a/blog/slewing-bearing-service-life-and-influencing-factors.html