Maintaining a vibrating screen is essential to ensure its efficient operation and long service life. Regular maintenance helps prevent unexpected breakdowns, reduce el tiempo de inactividad, and ensures consistent screening performance.

mantenimiento de cribas vibratorias

1. Inspección regular

Daily Checks:

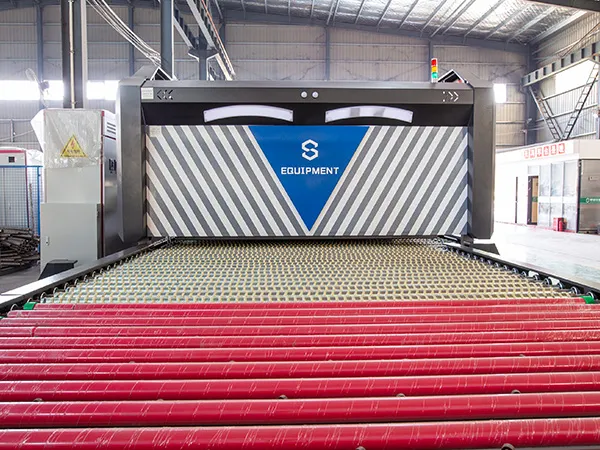

Inspect the screen surface for wear, daño, or clogging.

Check for any unusual noise or vibration during operation.

Ensure that the screen tension is appropriate and that all bolts are securely tightened.

Weekly Checks:

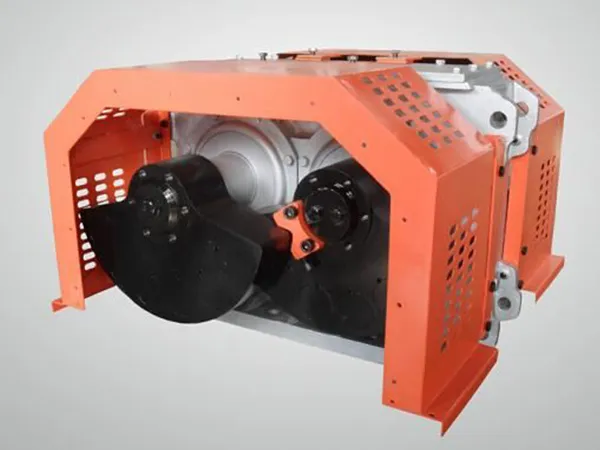

Inspect the vibrator motor for any signs of overheating or unusual sounds.

Check the springs for signs of fatigue, grietas, or breaks.

Inspect the drive belts for wear and proper tension.

Ensure that all bearings are in good condition and properly lubricated.

Monthly Checks:

Inspect the entire frame for cracks, corrosión, o deformación.

Check the condition of the screen panels or meshes and replace them if necessary.

Ensure that the motor mountings are secure and aligned properly.

2. Limpieza

Clean the Screen Surface:

Regularly clean the screen to remove any material buildup that could cause clogging or reduce screening efficiency.

Use appropriate cleaning tools or compressed air, but avoid harsh tools that could damage the screen mesh.

Remove Debris from the Machine:

Clean the area around the vibrating screen to prevent debris from interfering with the machine’s operation.

3. Lubricación

Bearing Lubrication:

Lubricate all bearings as per the manufacturer’s recommendations, typically using a grease gun.

Use the correct type of grease and avoid over-lubrication, which can cause overheating.

Motor Lubrication:

Some motors may require periodic lubrication; follow the manufacturer’s guidelines.

4. Tightening and Alignment

Check Bolts and Fasteners:

Regularly inspect and tighten all bolts and fasteners to prevent loosening due to vibration.

Ensure Proper Alignment:

Make sure the screen is properly aligned with other equipment in the production line to avoid unnecessary stress on the machine.

…

For more detailed information on vibrating screen maintenance, por favor haga clic aquí: https://www.zexciter.com/en/a/news/vibrating-screen-maintenance.html