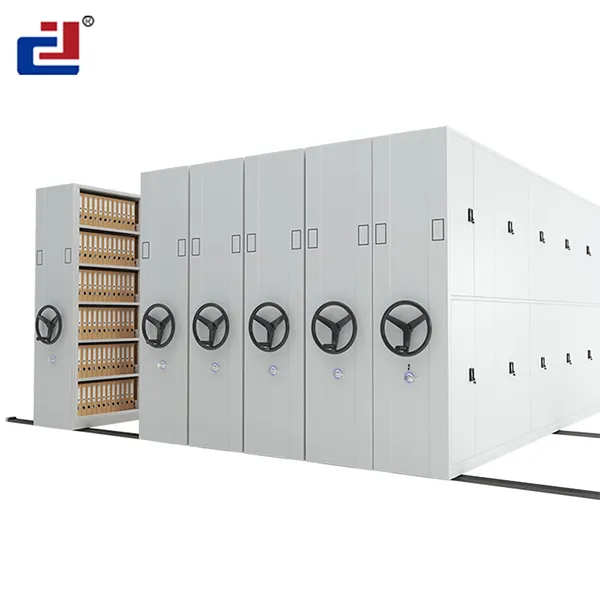

Maintaining steel bookshelves is relatively straightforward, thanks to their durability and resistance to common issues like warping and pest damage. Regular maintenance ensures they remain in good condition and continue to provide safe and reliable storage.

Steel Bookshelf Maintenance

1. Limpieza periódica:

Dusting: Regularly dust the shelves using a soft cloth or duster. This prevents dust buildup, which can detract from the appearance and cause items on the shelves to become dusty.

Cleaning Spills: Immediately clean any spills to prevent stains or corrosion. Use a mild detergent and water solution, and dry the area thoroughly to avoid moisture accumulation.

2. Inspect for Damage:

Rust and Corrosion: Periodically inspect the shelves for any signs of rust or corrosion, especially in humid environments or if the shelves are exposed to moisture. If rust is found, clean the area with a rust remover and apply a rust-resistant paint or finish.

Surface Scratches: Check for scratches or nicks in the finish, which can expose the metal to the risk of rust. Touch up any damaged areas with paint or a protective coating designed for metal surfaces.

3. Integridad estructural:

Weight Distribution: Ensure that the weight is evenly distributed across the shelves to prevent bending or warping. Avoid overloading the shelves beyond their designed weight capacity.

Check Fasteners: Regularly check and tighten any screws, perno, or other fasteners. Vibrations or heavy use can sometimes loosen these components, which may affect the stability of the shelves.

…

For more detailed information on steel bookshelf maintenance, por favor haga clic aquí: https://www.etegreen.com/en/a/news/steel-bookshelf-maintenance.html