In the production process of lost foam, model manufacturing is an important link. The selection of EPS raw materials, the accuracy of model processing, the density of the model, and the thermal decomposition products during casting all have important influences on obtaining high-quality castings.

1) Model manufacturing

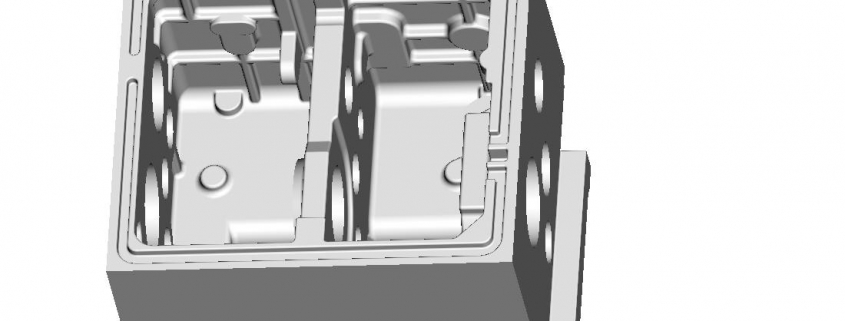

At present, the common mold making methods are as follows:

A) cutting and adhering with EPS sheet;

B) design drawings by themselves, and external processing;

C) Self-made simple prefabricated equipment.

The use of the above method to produce models generally does not pay attention to the phenomenon of density change of the pattern, especially when it is difficult to control the moisture in the processing of the external factory, and often there is a phenomenon that the molten iron is sprayed backwards or the castings are cold and poorly poured.

Therefore, in the production process, by strengthening the test of the density of the model, increasing the drying time of the model and other measures to solve, if conditions permit, it is best to slowly dry with an electric kiln to ensure that the drying is slow and complete, and the appearance is not deformed. After the EPS particles are selected by experiment, they cannot be changed arbitrarily and strictly tested.

2) Problems with vibration

Vibration compaction is the four key technologies of the lost mode. The vibration action causes the dry sand to generate dynamic flow in the flask, which improves the solidity and density of the dry sand and prevents casting defects. In the dry sand vibration filling, the ideal state is: the dry sand is in an orderly flow during the vibration process, and the model is uniformly deformed to uniformly fill the various parts of the model to make the model obtain higher and more uniform. Filling density.

However, in the process of vibration, the phenomenon of pattern deformation and cracking of the coating layer often occurs. The analysis mainly involves the phenomenon that the excitation force is too large, and the polarization block of the same group of motors is unbalanced. Therefore, the vibration force, amplitude and vibration time are mainly adjusted. For large and simple castings, vertical or horizontal vibrations can be used to reduce the amplitude. In addition, the sand particle size is reasonable, which can ensure the tightness and ensure the breathability.

3) Problems with the use of paint

In the lost foam casting, the use of the coating can improve the strength and rigidity of the pattern, and isolate the EPS pattern from the sand type to prevent the occurrence of sticking sand and mold collapse. During the casting process, the pyrolysis products of the pattern are smoothly discharged through the coating. The layer is generally composed of a refractory material, a binder and a suspending agent. A proper ratio of each composition is required to achieve good results. If the ratio and preparation process are changed at will, the performance of the coating will be greatly reduced. Such as reducing aggregates, reducing suspending agents, mixing time and so on.

In the drying process of the pattern, the first drying can be carried out completely for the next spraying, and the moisture can not be stored in the pattern. Sometimes only the drying method is adopted in summer. Due to the slow drying time, the uniformity of the coating is lowered, and the drying is not thorough, which causes the sand to be partially stuck in the casting, and causes back spray or pores during pouring. In addition, the thickness of the coating should vary with the wall thickness of the casting, and the thick-walled casting should be thicker and thinner. The coating is preferably sprayed to ensure a uniform coating.

4) Problems in the pouring process

For lost foam casting, in order to remove gas and vaporized residue during casting, the sprue should have sufficient height to ensure that the molten metal has sufficient pressure head. The pouring cup should be large enough to make the molten metal fill quickly, to ensure the contour of the casting is clear. Since the lost foam casting adopts the negative pressure dry sand vacuum vibration modeling, the casting strength is much larger than the wet strength and the negative pressure is adopted. The method can improve the stability of the mold. It is necessary to promptly remove the pyrolysis oxidation products generated during the gasification of the sample. If it is not handled properly, it will cause casting defects.

Therefore, the negative pressure is adjusted according to the actual situation in production. When pouring, start pouring slowly and then pour quickly to ensure that the gas is smoothly discharged from the mold.