https://www.ls-casting-mold.com/wp-content/uploads/2024/05/Bunk-Bed-Round-Tube.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 10:12:202024-07-27 10:12:20What is the installation process of metal folding bed?

https://www.ls-casting-mold.com/wp-content/uploads/2023/07/未标题-1.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

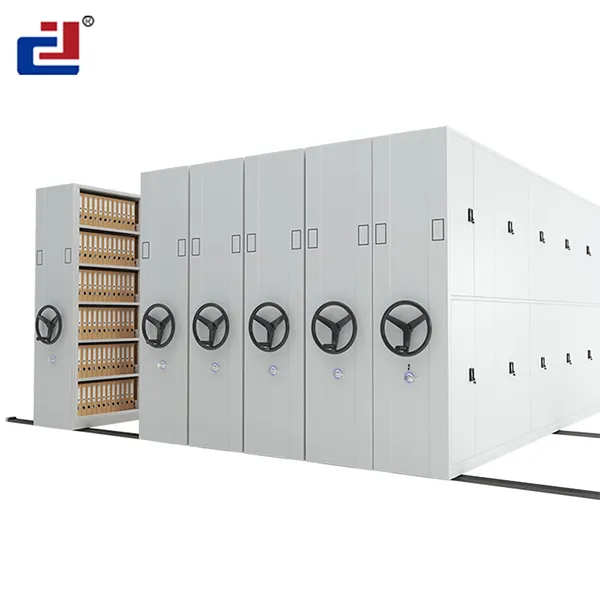

lsmojv2024-07-27 10:06:252024-07-27 10:06:25How does a mobile compactor work?

https://www.ls-casting-mold.com/wp-content/uploads/2024/06/1.jpg

600

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 10:00:362024-07-27 10:00:36What are the dimensions of file cabinets?

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

0

0

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 09:55:432024-07-27 09:55:43What are the dimensions and specifications of steel instrument cabinets?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 09:46:422024-07-27 09:46:42What is the correct use of tempering furnace convection?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 09:33:322024-07-27 09:37:05Glass Tempering Furnace Guide: Working Principle, Applications, Tempered Glass Types

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-27 09:25:392024-07-27 09:25:46What is the price of glass tempering furnace and what are the factors affecting the price?

https://www.ls-casting-mold.com/wp-content/uploads/2024/04/4.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-26 16:26:122024-07-26 16:26:12What is the glass tempering furnace process?

https://www.ls-casting-mold.com/wp-content/uploads/2024/05/46.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2024-07-26 16:03:042024-07-26 16:03:04How to calculate the design of vibrating feeder

https://www.ls-casting-mold.com/wp-content/uploads/2024/07/3.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

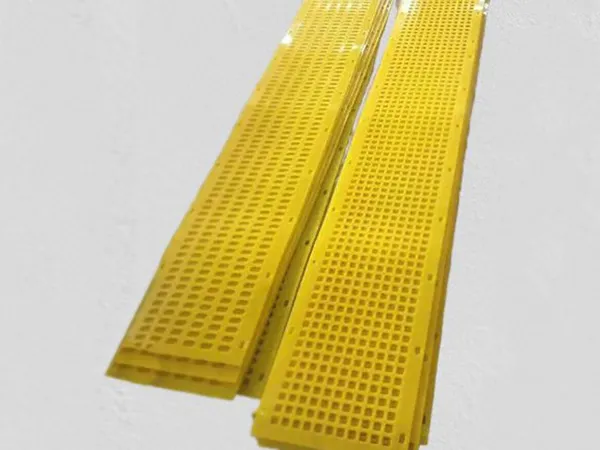

lsmojv2024-07-26 15:55:552024-07-26 15:55:55What are the installation methods of vibrating screen mesh?

Scroll to top