Industrial oil burners play a crucial role in manufacturing and processing industries, from heating large boilers to powering industrial furnaces. While their operation may seem complex to beginners, understanding their components, functions, and operation step by step can make them easy to grasp. This guide breaks down industrial oil burners in a clear and practical way.

Why Industrial Oil Burners Are Essential for Your Factory

Every efficient industrial operation relies on reliable heat sources. Here’s why industrial oil burners matter:

Maximized Energy Output: Properly designed burners extract the most heat from every drop of fuel.

Consistent Performance: Stable flames ensure uninterrupted operations, minimizing downtime.

Cost Efficiency: Efficient fuel usage lowers operational expenses.

Environmental Compliance: Modern burners reduce emissions, helping your factory meet safety and environmental standards.

Choosing the right burner isn’t just about heat—it’s about efficiency, safety, and cost savings.

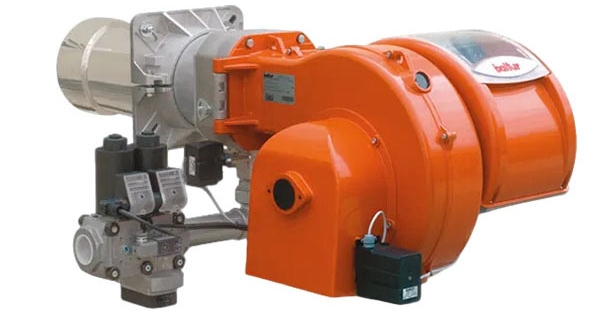

Key Components of an Industrial Oil Burner

Each part of an industrial oil burner is designed to ensure efficient, reliable, and safe combustion:

Nozzle: Atomizes fuel oil into a fine mist, promoting complete combustion.

Burner Head: Where air and fuel mix to sustain combustion.

Fan/Blower: Supplies air at the correct pressure to stabilize the flame and optimize efficiency.

Control System: Electronic or electric systems regulate ignition, fuel flow, and safety mechanisms.

Together, these components maximize heat output while minimizing fuel wastage and harmful emissions.

How They Mix Fuel and Air for Maximum Efficiency

Efficiency is all about the perfect mix:

Fuel Injection: Atomizes oil into tiny droplets for better combustion.

Air Mixing: Fan ensures the optimal air-to-fuel ratio.

Ignition: Spark or pilot flame starts the combustion instantly.

Sustained Heat: Continuous fuel and air flow maintain stable, reliable flames.

Smart mixing means more energy, less soot, and cleaner emissions—translating directly into savings.

Operating an Industrial Oil Burner Safely and Efficiently

Correct operation ensures longevity and safety:

Startup: Inspect for leaks, activate the control system, and ignite the burner.

Adjust Efficiency: Monitor flame and temperature; adjust fuel and air for optimal combustion.

Shutdown: Follow cooling procedures and close fuel valves before maintenance.

…

For more detailed information on energy-efficient industrial oil burner solutions for modern factories, please click here: https://www.sxburner.com/a/news/how-industrial-oil-burners-work.html