Continuous casting has become a core process in modern metal manufacturing, and graphite continuous casting molds play an indispensable role in ensuring stable production and high-quality metal outputs. With their unique thermal, mechanical, and chemical properties, graphite molds enable manufacturers to achieve greater efficiency, consistency, and cost savings. This article explores how graphite continuous casting molds work and how to optimize them for long-term performance.

What Are Graphite Continuous Casting Molds?

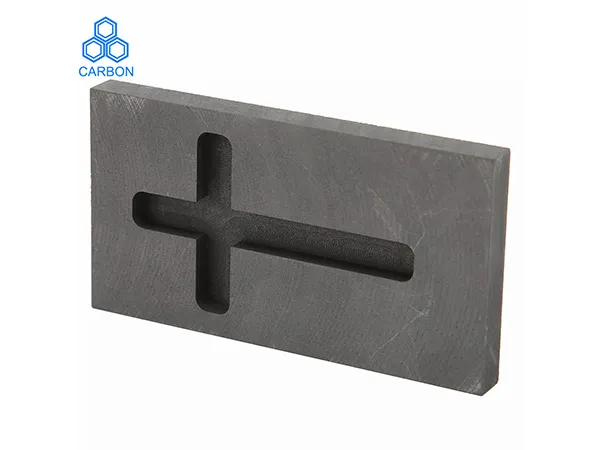

Graphite continuous casting molds are precision-engineered components made from high-density, fine-grain graphite materials. They are designed to shape molten steel, copper alloys, aluminum, and other non-ferrous metals into billets, rods, tubes, or other continuous profiles.

Compared with traditional molds made from copper or steel, graphite molds offer several distinct advantages:

Exceptional thermal conductivity for faster, more uniform cooling

Low friction and self-lubricating performance to reduce surface defects

High temperature and oxidation resistance, ideal for harsh casting environments

Minimal thermal expansion, ensuring dimensional accuracy

Longer service life, lowering the overall production cost

These characteristics make graphite molds a preferred choice for modern high-speed casting lines.

How Graphite Continuous Casting Molds Work

The working principle of graphite continuous casting molds centers around controlled cooling, continuous metal flow, and stable mold–metal interaction.

1. Molten Metal Feeding

Molten metal is poured into the inlet of the graphite mold at a precisely controlled temperature. Before casting begins, the mold is coated with a lubrication agent to reduce friction, prevent sticking, and protect the mold surface.

2. Heat Transfer and Initial Solidification

Graphite’s high thermal conductivity allows rapid heat absorption from the molten metal. As heat is extracted, a solidified metal shell begins forming along the mold wall while the interior remains partially molten.

This controlled thermal gradient is essential for creating a stable casting structure.

…

For more detailed information on the working principle of graphite continuous casting molds, please click to visit: https://www.czgraphite.com/a/news/how-graphite-continuous-casting-molds-work.html