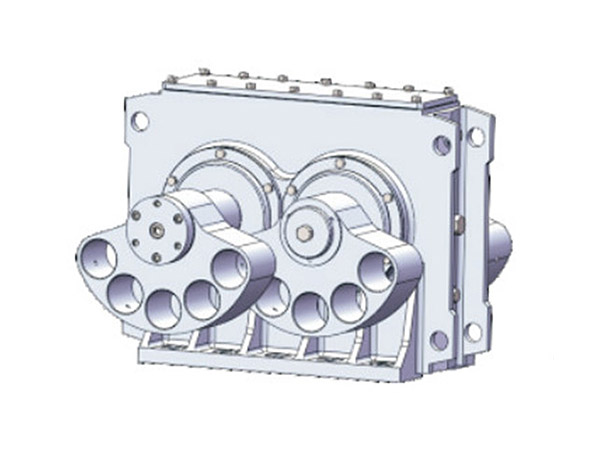

As industries such as mining, sand and gravel, chemicals, and metallurgy continuously increase their demands for screening efficiency and product quality, the importance of vibrating screen exciters is becoming increasingly prominent. As the core power source of the vibrating screen, it determines the amplitude, frequency, stability, and screening capacity of the entire machine.

For companies looking to purchase or upgrade equipment, the most pressing questions are: “How much does a customized vibrator cost?”, “Why are there such large differences in quotes from different manufacturers?”, and “How can I determine if a quote is reasonable?”

Custom Vibrating Screen Exciter Price and Quotation

This article will provide a comprehensive analysis from a professional perspective, examining influencing factors, pricing logic, supplier comparison strategies, and common purchasing questions to help companies select equipment with lower risk and higher cost-effectiveness.

1. What Determines the Price of a Custom Vibrating Screen Exciter?

Factors influencing the price of custom vibrating screen exciters are often overlooked, but they determine the reliability and lifespan of the equipment.

1.1 Material Selection and Structural Strength

Vibrating screen exciters need to withstand prolonged high-frequency vibrations, therefore the grade of materials directly affects product cost:

High-strength forged steel housing: Enhanced fatigue resistance, suitable for heavy-duty screening

Wear-resistant alloy gears: Reduced wear, increased lifespan

High-quality bearings (imported/high-temperature resistant): Significantly reduces downtime probability

Upgraded sealing structure (labyrinth seal, double oil seal): Improved dustproof and waterproof ratings

If the equipment is used with wet materials, corrosive materials, or high-dust environments, manufacturers typically employ anti-corrosion coating + reinforced sealing design, naturally increasing the price.

1.2 Excitation Power and Motor Specifications

The power system is a key factor affecting cost, including:

Drive method: Electric / Hydraulic / Pneumatic

Power output: Higher power means higher cost

Continuous operation level (S1, S2, S3)

Energy efficiency level (e.g., IE2/IE3 high-efficiency motors)

High-end exciters typically use:

Custom-wound motors

…

For more detailed information on pricing and quotes for customized vibrating screen exciters, please click here:https://www.hsd-industry.com/news/custom-vibrating-screen-exciter-price-and-quotation/