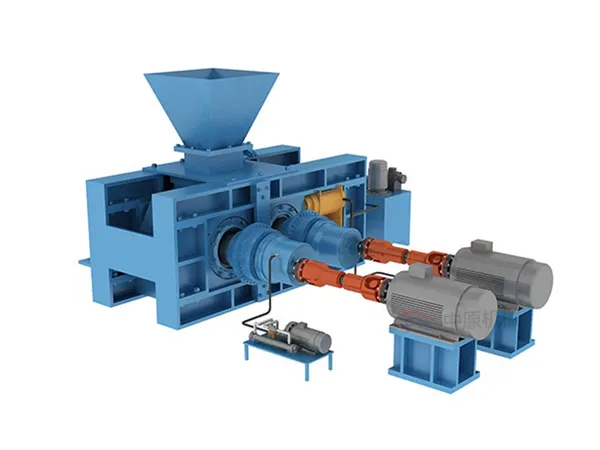

High-pressure grinding rolls (HPGR) are indispensable in modern mining and cement production, valued for their energy efficiency, high throughput, and ability to produce finely crushed, uniform material. However, as with any heavy-duty industrial equipment, HPGRs face inevitable wear and tear, which can compromise performance and increase maintenance costs. Extending the service life of these rolls is essential for maintaining consistent production and reducing operational expenses.

How to Extend the Service Life of High-Pressure Grinding Rolls

1. Invest in High-Quality Wear-Resistant Rolls

The durability of an HPGR largely depends on the quality of its rolls. Selecting wear-resistant steel or advanced composite materials can drastically reduce surface wear and deformation. Some manufacturers also offer rolls with specialized coatings or surface treatments that improve hardness and abrasion resistance, extending service life by up to 30% under high-load conditions.

2. Conduct Routine Inspections and Monitoring

Regular maintenance is key to detecting issues before they escalate. Inspect rolls frequently for cracks, surface wear, or uneven pressure distribution. Modern HPGRs can integrate real-time monitoring sensors for temperature, vibration, and load, allowing operators to plan maintenance proactively and minimize unexpected downtime.

…

For more detailed information on strategies to extend the service life of high-pressure roller mills, please click to visit:https://www.zymining.com/en/a/news/how-to-extend-the-service-life-of-high-pressure-grinding-rolls.html