Graphite and its advanced derivatives, like carbon-carbon composites (CFC), are indispensable materials in the modern heat treatment industry. Their unique combination of thermal, chemical, and physical properties makes them superior to metals and ceramics for many high-temperature applications. Heat treatment processes—such as annealing, hardening, brazing, sintering, and carburizing—rely on precise temperature control in highly demanding environments, conditions for which graphite is exceptionally well-suited.

Key Properties of Graphite for Heat Treatment

Before diving into the applications, it’s crucial to understand why graphite is the material of choice.

High-Temperature Stability: Graphite does not melt at atmospheric pressure; it sublimes at approximately 3,650°C (6,600°F). Its mechanical strength actually increases with temperature, peaking at around 2,500°C, a property unmatched by metals which weaken significantly as they get hotter.

Excellent Thermal Shock Resistance: Graphite can withstand rapid heating and cooling cycles without cracking or failing. This is due to its high thermal conductivity and very low coefficient of thermal expansion.

Chemical Inertness: In a vacuum or an inert/reducing atmosphere, graphite is extremely stable and does not react with most metals, alloys, or process gases, preventing contamination of the workpieces.

High Thermal Conductivity: It efficiently and uniformly transfers heat, which is critical for ensuring that all parts in a furnace load reach the same temperature at the same time.

Low Coefficient of Thermal Expansion (CTE): Graphite expands and contracts very little with temperature changes. This dimensional stability is crucial for fixtures and jigs that must hold parts to tight tolerances throughout a heat treatment cycle.

Machinability and Design Flexibility: Despite its hardness, graphite is easily machined into complex shapes, allowing for the creation of custom fixtures, heating elements, and intricate furnace components.

Lightweight: Graphite has a low density compared to refractory metals like molybdenum or tungsten, making furnace fixtures easier to handle and reducing the thermal mass of the furnace, which can lead to faster cycle times and energy savings.

Electrical Conductivity: This property allows graphite to be used directly as a resistive heating element, simplifying furnace design.

Major Applications of Graphite Products

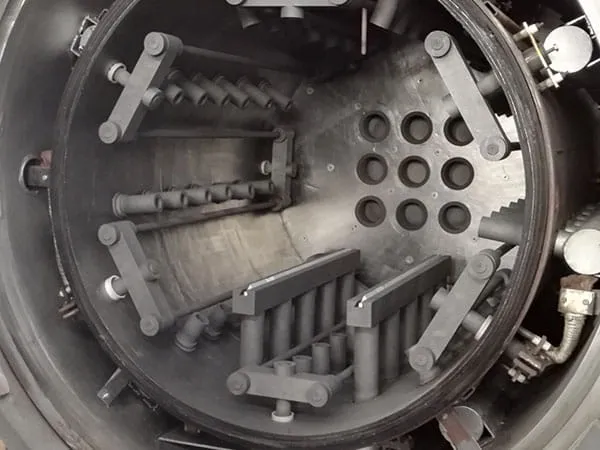

Graphite products are used extensively for both the internal components of the furnace (“the hot zone”) and for the tooling that holds the workpieces.

…

For more detailed information on the advantages of graphite products in the heat treatment industry, please click here:https://www.czgraphite.com/a/news/application-of-graphite-products-in-heat-treatment-industry.html