In mining, quarrying, and aggregate processing, screening efficiency directly impacts production output and operating costs. While many operators focus on screen size or mesh selection, exciter power is often underestimated.

From a vibrating screen manufacturer’s perspective, exciter power determines how effectively vibration energy is transferred to the material. When properly matched, it improves separation accuracy, stabilizes throughput, and extends equipment service life. When misapplied, it leads to poor screening results, excessive wear, and unnecessary energy consumption.

What Is Exciter Power in a Vibrating Screen?

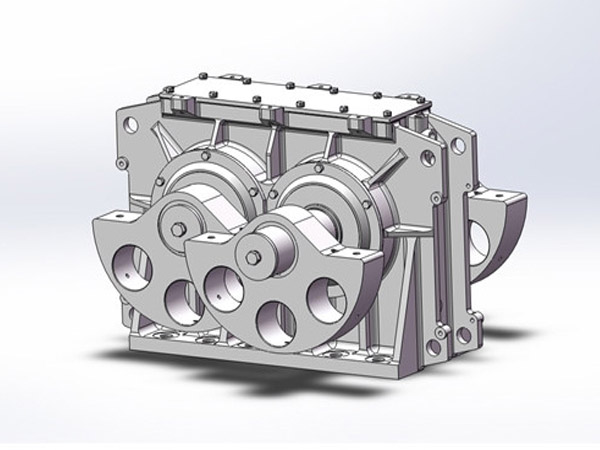

The exciter is the vibration-generating unit of a vibrating screen. Driven by an electric motor, it creates controlled oscillation through eccentric shafts or blocks. Exciter power, typically expressed in kilowatts (kW), defines the amount of energy available to generate vibration force.

In equipment design, exciter power is selected together with:

Vibration frequency

Amplitude

Screen mass and structure

Material load conditions

It is not an isolated parameter, but part of a complete vibration system.

How Exciter Power Influences Screening Efficiency

Material Stratification and Separation Accuracy

Effective screening relies on proper material stratification. Fine particles must move downward to the screen surface, while coarse particles travel toward discharge.

Low exciter power results in insufficient material lift and poor stratification

Fine particles remain trapped, reducing screening efficiency

Optimized exciter power promotes uniform material movement and improves separation accuracy across the entire screen deck

…

For more detailed information on how vibrating screen power affects screening efficiency, please click to visit: https://www.hsd-industry.com/news/how-exciter-power-affects-screening-efficiency/