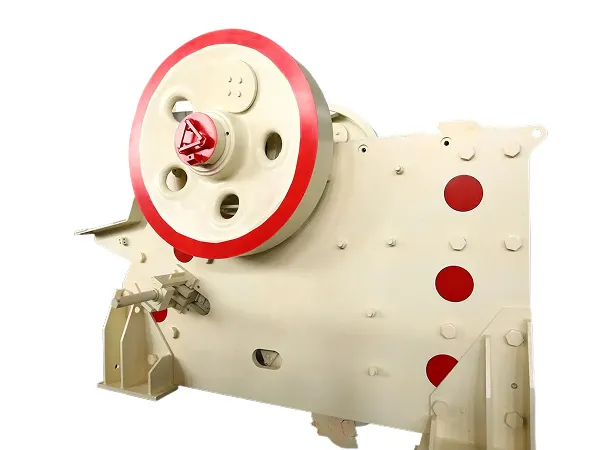

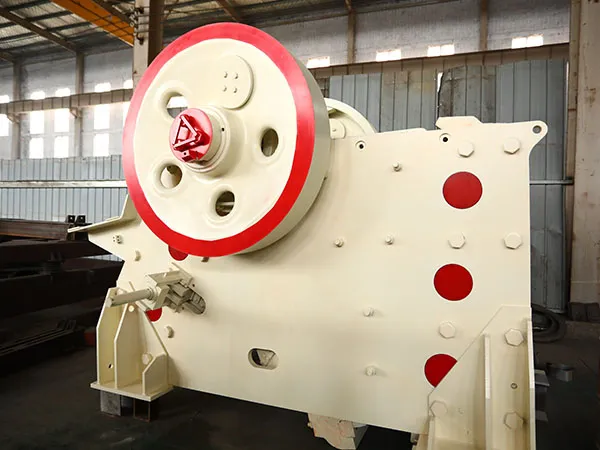

Jaw crushers are widely used in mining, building materials processing, and metallurgical industries. Their output directly determines the efficiency and cost control of the entire production line. However, in actual operation, many users find that even with correct equipment selection, the actual output is far lower than the design value.

The insufficient output of jaw crushers is often not caused by a single fault, but by a combination of factors such as feeding, parameter settings, wear conditions, and operating methods. This article will analyze the key factors affecting jaw crusher output based on field practice and provide actionable optimization suggestions to help you quickly improve crushing efficiency.

Causes and Solutions for Insufficient Output of Jaw Crushers

1. Feed particle size is too large or uneven

Feed size exceeding the design range, or excessive particle size fluctuations, will lead to unstable crushing chamber load, affecting the effective crushing time of the jaw plates, and ultimately reducing overall output.

Optimization suggestions:

Control the feed particle size to not exceed the maximum allowable feed size of the equipment.

Improve feed uniformity through screening or pre-crushing equipment.

2. Improper Discharge Opening Size Adjustment

The discharge opening directly determines the product particle size and processing capacity:

Discharge opening too large: Short material residence time, insufficient crushing.

Discharge opening too small: Prone to material blockage, machine stalling, and frequent shutdowns.

Optimization Recommendation: Regularly calibrate the discharge opening parameters according to material hardness, moisture content, and target output to avoid “one-time setting without long-term adjustment.”

3. Severe Wear of Jaw Plates, Bearings, and Other Components

Jaw plate wear reduces biting force, while abnormal bearings increase operating resistance; both significantly affect the effective capacity of the jaw crusher.

Optimization Recommendation:

Regularly check the jaw plate tooth profile and thickness.

Check the bearing condition promptly if abnormal vibration or temperature rise occurs.

Use highly wear-resistant materials to improve continuous operation capability.

4. Decreased Efficiency of Motor and Transmission System

Common problems include:

Unstable motor speed

Belt slippage or aging

Poor gear meshing

These problems directly cause power loss, making the equipment appear to be running, but actually inefficient.

Optimization suggestions:

Regularly adjust belt tension

Check motor load and power matching

Ensure proper lubrication of the transmission system

5. Non-standard operation leads to efficiency loss

Improper operating habits can also silently reduce output, for example:

…

For more detailed information on what to do if your jaw crusher’s output is insufficient, please click to visit: https://www.yd-crusher.com/a/news/jaw-crusher-output-insufficient.html