Offshore wind towers are critical components of modern renewable energy infrastructure, providing the foundation for wind towers installed in marine environments. Their manufacturing process is highly specialized, requiring high-quality wind tower welding production line,precision engineering, advanced welding techniques, and strict quality control to ensure long-term performance in harsh offshore conditions. From steel plate rolling and section welding to surface treatment and final assembly, each stage of production is designed to deliver structural stability, corrosion resistance, and the ability to withstand extreme wind and wave loads. Understanding the manufacturing process of offshore wind towers helps highlight the complexity, technological innovation, and stringent standards behind the development of these essential structures in the global transition to clean energy.

Offshore Wind Towers Manufacturing Process

1. Material Sourcing and Preparation:

The primary material for wind towers is high-strength steel. Large steel plates, often several meters wide and thick, are sourced from specialized steel mills. These plates undergo initial inspection for defects and are then cut to the required dimensions using laser or plasma cutting machines.

2. Plate Rolling:

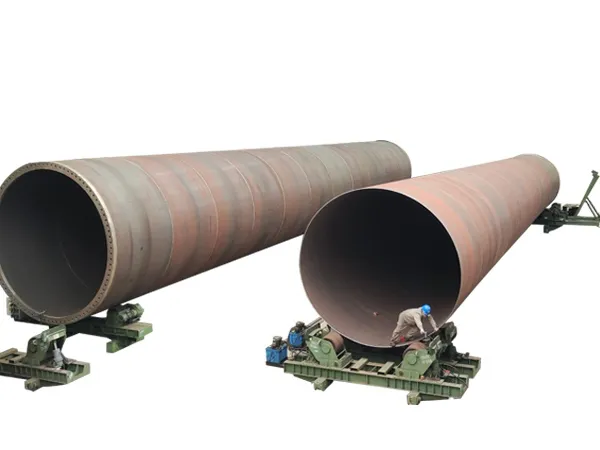

The flat steel plates are then rolled into cylindrical or conical sections. This is achieved using large rolling machines that gradually bend the steel into the desired curvature. The rolling process requires precision to ensure the correct diameter and seamless fit for subsequent sections.

3. Longitudinal Welding:

Once rolled, the edges of each steel section are welded together to form a complete cylinder. This is typically done using automated submerged arc welding (SAW) or gas metal arc welding (GMAW) processes, which provide strong and consistent welds. Multiple weld passes may be required due to the thickness of the steel.

4. Section Assembly (Can Assembly):

Several individual cylindrical or conical sections are then assembled to form larger tower sections, often called “cans.” This involves fitting the ends of the rolled and welded sections together and performing circumferential welds. Again, automated welding techniques are commonly used to ensure high-quality, continuous welds.

5. Flange Welding:

Flanges, which are large, thick steel rings, are welded to the ends of each tower section. These flanges are critical for connecting the tower sections together at the installation site using high-strength bolts. The welding of flanges requires extreme precision to ensure perfect alignment.

6. Internal Components and Access:

…

More detailed information about the manufacturing process of offshore wind towers can be found here: https://www.bota-weld.com/en/a/news/offshore-wind-towers-manufacturing-process.html