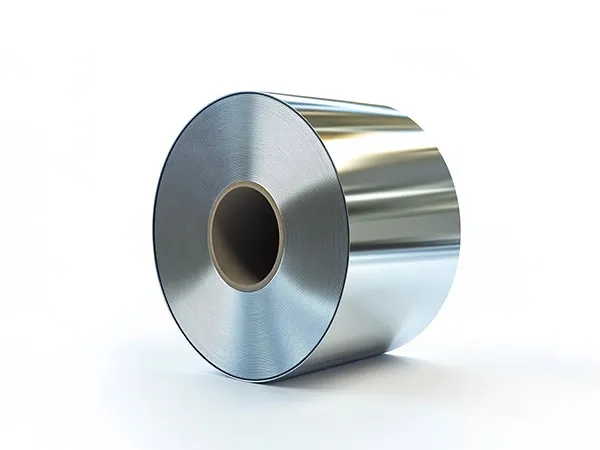

Aluminum coils are essential in modern industrial, construction, and architectural projects, offering lightweight, durable, and corrosion-resistant solutions. Choosing the right aluminum coil finish—pre-painted aluminum coils or anodized aluminum coils—can significantly influence both performance and appearance. Understanding their benefits, applications, and differences helps manufacturers, designers, and engineers make informed material decisions.

Pre-Painted Aluminum Coils: Stylish, Protective, and Customizable

Pre-painted aluminum coils, also known as PVDF or coil-coated aluminum, are coated with a protective paint layer during production. This coating enhances aesthetics with vivid colors, textures, and finishes, while also improving corrosion resistance and weather durability.

Key Benefits:

Customizable Appearance: Wide range of colors, textures, and finishes for architectural panels and industrial applications

Long-Lasting Protection: Resistant to UV, moisture, and environmental pollutants

Low Maintenance: Smooth surfaces are easy to clean and maintain

Typical Applications:

Building facades, roofing panels, and cladding

Signage, advertising boards, and decorative elements

Interior and exterior architectural designs

Anodized Aluminum Coils: Durable, Scratch-Resistant, and Eco-Friendly

Anodized aluminum coils undergo an electrochemical process that thickens the natural oxide layer, producing a hard, corrosion-resistant surface. Unlike paint, anodizing penetrates the aluminum itself, offering durability and longevity without added bulk.

…

For more detailed information on the differences between pre-coated aluminum coils and anodized aluminum coils, please click to visit:https://www.dw-al.com/a/news/pre-painted-vs-anodized-aluminum-coils.html