Selecting the right precision crossed roller bearing size involves considering several key factors to ensure optimal performance in your application.

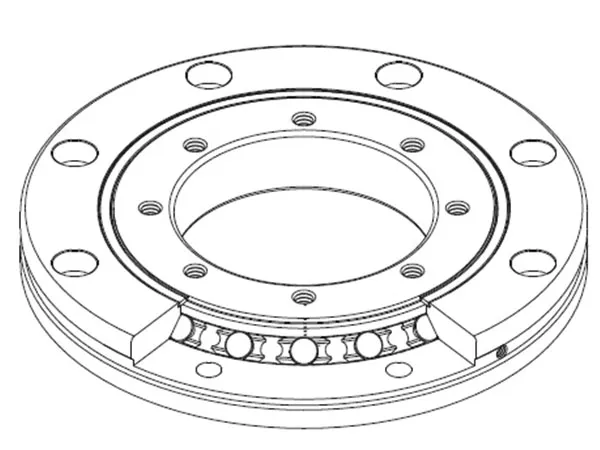

Precision Crossed Roller Bearing Size Selection Guide

1. Determine Load Requirements

Radial Load (Fr): The force perpendicular to the shaft.

Axial Load (Fa): The force parallel to the shaft.

Moment Load (M): The tilting or overturning force.

Crossed roller bearings handle combined loads (radial, axial, and moment) efficiently. Calculate the expected loads and refer to the bearing’s dynamic (Cr) and static (Cor) load ratings.

2. Consider Bearing Dimensions

Inner Diameter (ID): Match the shaft size.

Outer Diameter (OD): Ensure it fits within the housing.

Width (Height): Check space constraints.

Standard sizes range from small (e.g., 10mm ID) to large (e.g., 500mm ID).

3. Check Rotational Accuracy & Rigidity

Precision bearings (e.g., ABEC-5, ABEC-7, P4, P2) have tighter tolerances.

For high rigidity, select a bearing with preload (eliminates internal clearance).

4. Speed Requirements

Check the limiting speed (rpm) based on lubrication and cage material.

Polyamide cages allow higher speeds than steel cages.

5. Mounting Configuration

Inner/Outer Ring Rotation: Decide if the inner or outer ring rotates.

Split vs. Non-Split Design: Split types (e.g., XR series) are easier to install.

6. Environmental Conditions

Lubrication: Grease (standard) or oil (high-speed).

Sealing: Optional seals for dust/moisture protection.

Material: Stainless steel (corrosion resistance) or standard chrome steel.

…

For more detailed information on how to choose the appropriate precision crossed roller bearing size, please visit: https://www.lynicebearings.com/a/bearing-faqs/precision-crossed-roller-bearing-size-selection.html