Briquetting machines are powerful tools that compact various types of waste materials into dense, solid briquettes. These briquettes can then be used as a renewable energy source. Let’s explore how these machines work and the benefits they offer.

How Briquetting Machines Transform Waste into Energy

The Briquetting Process

The process typically involves a few key steps:

Material Preparation: Raw waste materials, such as sawdust, agricultural residue (like rice husks or sugarcane bagasse), paper, or even certain plastics, are first prepared. This might involve drying the material to reduce moisture content and sometimes crushing or shredding it to a uniform size.

Feeding: The prepared material is fed into the briquetting machine’s hopper. From there, it’s typically moved into the compression chamber by a screw conveyor or similar mechanism.

Compression: This is the core of the briquetting process. Inside the machine, immense pressure is applied to the waste material. This pressure, often combined with heat generated by friction, causes the lignin (a natural binder in woody materials) or other binders (if added) to activate, fusing the particles together.

Ejection: Once compacted into a solid form, the briquette is ejected from the machine, ready for cooling and storage.

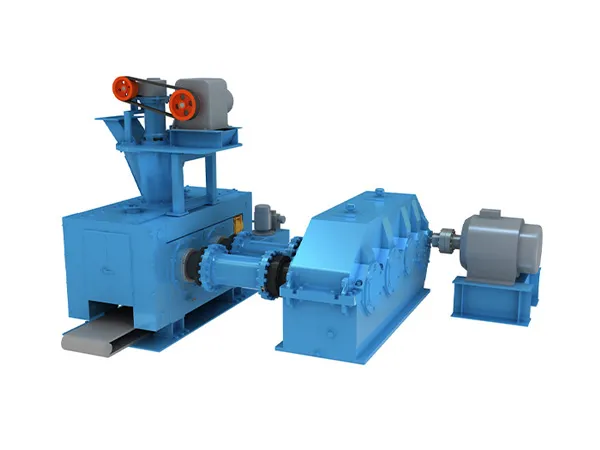

Types of Briquetting Machines

There are several types of briquetting machines, each suited for different materials and production scales:

Mechanical Briquetting Machines: These use a ram or punch to compress the material. They are often robust and good for high-volume production.

Hydraulic Briquetting Machines: These use hydraulic cylinders to exert pressure. They are versatile and can handle a wide range of materials, often producing very dense briquettes.

Screw Briquetting Machines: These use a rotating screw to compress and extrude the material through a die. They can achieve high densities and are particularly effective for materials with natural binders like lignin.

Benefits of Briquetting

Waste Reduction: Briquetting significantly reduces the volume of waste materials, making storage and transportation more efficient.

Renewable Energy Source: Briquettes are an excellent alternative to fossil fuels like coal. They burn cleanly and have a high caloric value, providing a sustainable energy source for industrial boilers, kilns, and even domestic heating.

…

More details on how briquetting machines can turn waste into energy can be found at: https://www.zymining.com/en/a/news/waste-to-energy.html