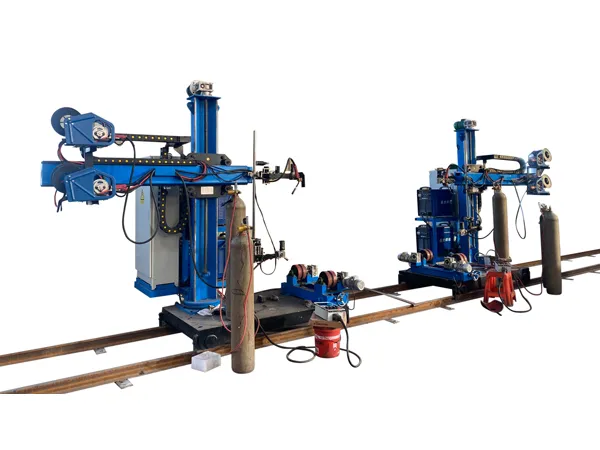

Welding manipulators are essential pieces of equipment in automated and semi-automated welding operations, designed to provide precise control over welding torches for consistent and high-quality welds. However, like all industrial machinery, welding manipulators are subject to wear, mechanical failures, and electrical issues over time. Knowing how to diagnose and repair a welding manipulator is crucial for maintaining production efficiency, ensuring workplace safety, and minimizing downtime.

Repairing a welding manipulator involves diagnosing common mechanical, electrical, and welding-related issues.

Welding Manipulator Repair

1. Identify the Problem

Before starting repairs, observe symptoms to narrow down the issue:

Mechanical Issues: Jerky movement, misalignment, excessive vibration, or unusual noises.

Electrical Issues: Power failure, motor not responding, or erratic control behavior.

Welding Issues: Poor arc stability, inconsistent wire feed, or irregular torch movement.

2. Common Repairs & Solutions

A. Mechanical Repairs

Check Rails & Guides

Issue: Misalignment or wear causing jerky movement.

Solution:

Clean and lubricate linear guides.

Adjust or replace worn-out rails/bearings.

Inspect Drive Mechanism

Issue: Faulty gears, belts, or chains.

Solution:

Tighten or replace loose/damaged belts/chains.

Grease gears or replace if teeth are worn.

Column & Boom Stability

Issue: Excessive vibration or wobbling.

Solution:

Tighten bolts and structural joints.

Check for cracks in the boom and repair with welding if needed.

B. Electrical & Motor Repairs

Motor Not Running

Check:

Power supply (fuses, breakers, voltage).

Motor brushes (for DC motors) or windings (for AC motors).

…