Choosing a suitable wind tower welding production line is a complex process that depends on several key factors related to your production requirements, financial constraints, and site-specific conditions. The primary goal is to find a system that maximizes efficiency and quality while being cost-effective.

Wind Tower Welding Production Line Selection

Phase 1: Foundational Analysis & Defining Your Requirements

Before you even look at a single piece of equipment, you must clearly define your operational needs.

1. Production Capacity & Takt Time

Target Output: How many towers (or tower sections/cans) do you need to produce per week, month, or year? This is the single most important factor.

Takt Time: Calculate the maximum time allowed to produce one unit to meet demand. This will determine the required welding speed and level of automation.

Shift Patterns: How many shifts will you run per day? A two-shift operation needs a more robust and faster line than a single-shift operation for the same annual output.

2. Tower Specifications (Current & Future)

Diameter Range: What is the minimum and maximum diameter of the tower sections you will produce? This dictates the size of your rolling machines and turning rolls.

Plate Thickness Range: What are the minimum and maximum steel plate thicknesses? This determines the required power of the welding sources, the choice of welding process (e.g., single-wire SAW vs. tandem or multi-wire SAW), and the power of the plate rolling machine.

Section Length: What is the standard length of a single “can” or section? This influences the length of the welding manipulators and the workshop layout.

Material Type: What grade of steel will you be using (e.g., S355, S460)? Different materials have different welding requirements.

Future Trends: Are towers getting taller, thicker, or using higher-strength steel? Plan for the future. Buying a line that is maxed out on day one is a poor investment. Consider a 5-10 year outlook.

3. Workshop Layout & Logistics

Available Space: Map out your facility. Consider the footprint of the entire line, including space for plate storage, work-in-progress (WIP), and finished section storage.

Ceiling Height & Crane Capacity: Do your overhead cranes have sufficient height and lifting capacity to handle the largest and heaviest tower sections? This is a frequent bottleneck.

Material Flow: Design a logical, linear flow from raw plate delivery to finished section painting and shipping to minimize handling time and costs.

4. Desired Level of Automation

Manual: Operator-intensive, suitable for very low volume or custom work. Not recommended for modern tower production.

Semi-Automated: A mix of automated welding processes with manual setup and positioning. A common and flexible choice.

Fully Automated: Integrated systems with CNC control, automated material transfer, laser seam tracking, and data logging. Higher initial cost but delivers the best consistency, speed, and lowest labor cost per unit.

Phase 2: Key Equipment Stations & Selection Criteria

A typical wind tower production line is a series of specialized stations. Here’s what to look for in each.

1. Plate Preparation Station

Function: Cutting plates to size and creating the weld bevels (V, X, or U grooves).

Key Equipment: CNC Plasma/Oxy-fuel Cutting Machine with a milling or plasma beveling head.

Selection Criteria:

Precision: High-precision cutting is essential for good fit-up and weld quality.

Beveling Capability: The ability to create accurate, consistent bevels in a single pass saves enormous time.

Table Size: Must accommodate your largest plates.

2. Plate Rolling Machine

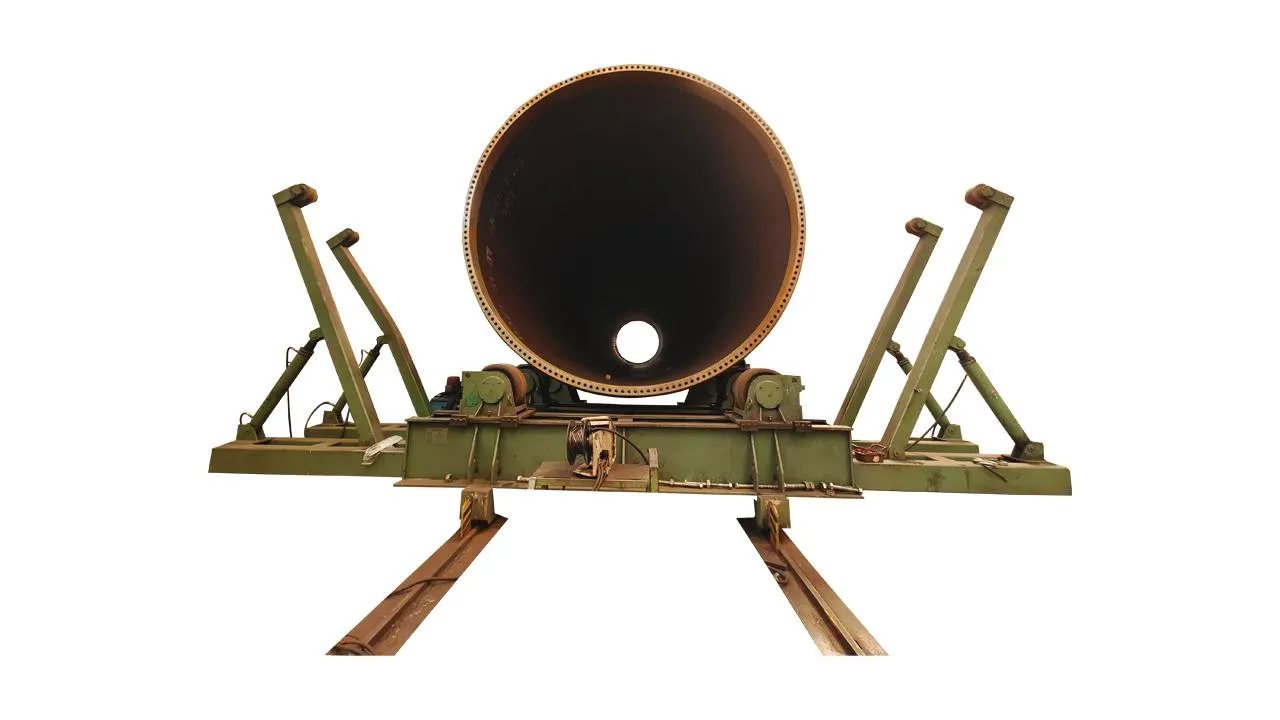

Function: Forming the flat plates into cylindrical or conical “cans.”

Key Equipment: 4-Roll Plate Bending Machine.

Selection Criteria:

Capacity: Must be rated for your maximum plate thickness and width.

4-Roll vs. 3-Roll: A 4-roll machine is superior for tower production. It allows pre-bending of the plate ends, minimizing the flat-end section and requiring less follow-up work.

…

For more detailed information on how to choose a suitable wind turbine tower welding production line, please click here: https://www.bota-weld.com/en/a/news/wind-tower-welding-production-line-selection.html