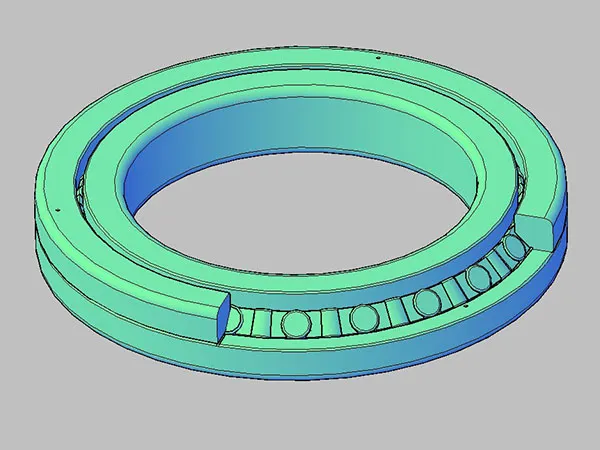

Rodamientos de rodillos cruzados de precisión are at the heart of modern high-precision machinery, desde robótica y equipos CNC hasta dispositivos aeroespaciales y médicos. Su diseño único proporciona una rigidez excepcional y una rotación suave., pero incluso las vibraciones más pequeñas pueden comprometer el rendimiento, reducir la vida útil del rodamiento, y afectar la precisión operativa. Para ingenieros y equipos de mantenimiento, Comprender cómo controlar la vibración es clave para mantener la eficiencia y la confiabilidad..

Reducción de la vibración en rodamientos de rodillos cruzados de precisión

Causas comunes de vibración en los rodamientos

La vibración en los rodamientos de rodillos cruzados de precisión puede deberse a varios factores:

Variaciones de fabricación: pequeñas inconsistencias en la geometría del rodillo o de la pista de rodadura pueden crear microvibraciones durante el funcionamiento..

Errores de instalación: la desalineación o las superficies de montaje desiguales pueden causar una distribución desigual de la carga., lo que resulta en oscilaciones no deseadas.

Fuerzas externas: cargas de choque, distribución desigual del peso, o el funcionamiento a alta velocidad pueden amplificar la vibración..

Problemas de lubricación: la lubricación inadecuada o inadecuada aumenta la fricción, que intensifica las vibraciones y el ruido de funcionamiento.

Estrategias efectivas para reducir la vibración

1. Garantizar una alineación precisa

La alineación adecuada entre el rodamiento y su alojamiento es fundamental. Incluso una ligera desalineación puede provocar oscilaciones. Utilice herramientas de alineación de precisión y siga las especificaciones de torsión del fabricante para obtener resultados óptimos..

…

Para obtener información más detallada sobre cómo minimizar la vibración en rodamientos de rodillos cruzados de precisión para lograr la máxima eficiencia, por favor haga clic aquí:https://www.lynicebearings.com/a/blog/reducing-vibration-in-precision-crossed-roller-bearings.html