https://www.ls-casting-mold.com/wp-content/uploads/2024/06/bucket-elevator.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 13:44:112025-11-27 13:44:11Posicionadores de soldadura de carga ajustable: Aumentar la precisión, Seguridad, y eficiencia en la soldadura moderna

https://www.ls-casting-mold.com/wp-content/uploads/2024/06/bucket-elevator.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 11:34:562025-11-27 11:34:56Consejos esenciales para el mantenimiento del posicionador de soldadura y guía de solución de problemas para un rendimiento confiable

https://www.ls-casting-mold.com/wp-content/uploads/2023/10/Skyhook-Welding-Positioner3.jpg

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 11:31:072025-11-27 11:31:07Cómo elegir el posicionador de soldadura adecuado para su fábrica

https://www.ls-casting-mold.com/wp-content/uploads/2022/03/20181211140425_4358.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

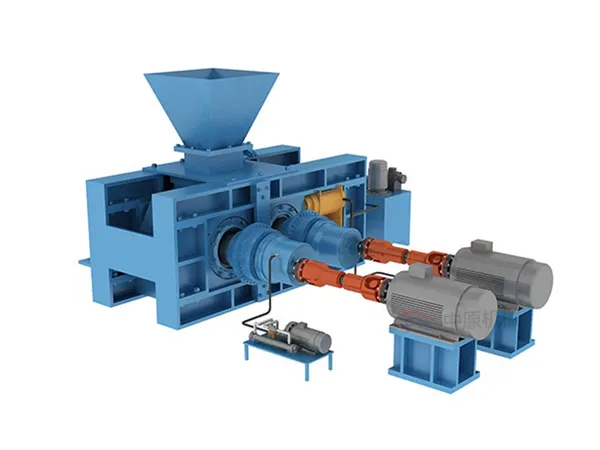

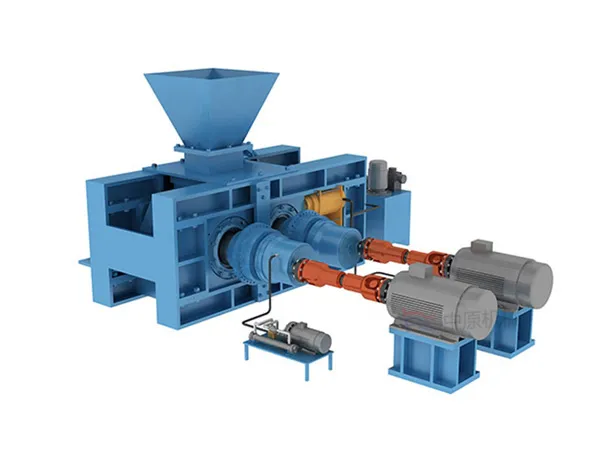

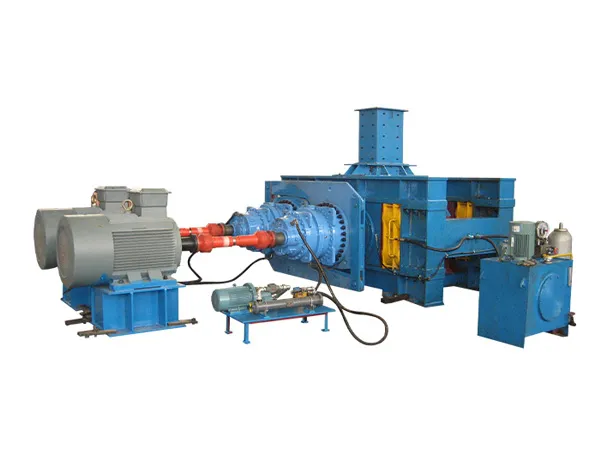

lsmojv2025-11-27 11:21:042025-11-27 11:21:046 Estrategias comprobadas para prolongar la vida útil de los rodillos abrasivos de alta presión (HPGR)

https://www.ls-casting-mold.com/wp-content/uploads/2022/03/20181211140425_4358.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:55:282025-11-27 10:55:28HPGR vs molinos de bolas: ¿Qué tecnología de molienda maximiza la eficiencia y reduce los costos en la minería??

https://www.ls-casting-mold.com/wp-content/uploads/2022/03/20181211140425_4358.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:43:092025-11-27 10:43:09Revolucionando la producción de fosfato: Cómo los rodillos abrasivos de alta presión aumentan la eficiencia y reducen los costos

https://www.ls-casting-mold.com/wp-content/uploads/2022/03/20181211140425_4358.jpg

450

700

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:37:552025-11-27 10:37:55Cómo los rodillos de molienda de alta presión mejoran la eficiencia de la molienda de cemento

https://www.ls-casting-mold.com/wp-content/uploads/2023/07/Double-banana-sieve-e1689989322808.png

400

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:21:202025-11-27 10:21:20Cómo las cribas vibratorias lineales de alta eficiencia mejoran el procesamiento de materiales y el rendimiento de la producción

https://www.ls-casting-mold.com/wp-content/uploads/2023/07/Double-banana-sieve-e1689989322808.png

400

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:14:492025-11-27 10:14:49Mantenimiento de pantallas industriales: Evite el tiempo de inactividad y optimice la eficiencia del cribado

https://Los siguientes fabricantes de máquinas para fabricar bolsas le brindarán una introducción detallada al rendimiento y las ventajas de

450

600

lsmojv

http://www.ls-casting-mold.com/wp-content/uploads/2018/12/lslogo-300x138.png

lsmojv2025-11-27 10:02:422025-11-27 10:02:42Cómo las cribas vibratorias lineales transforman el procesamiento de materiales en la fabricación moderna

Desplazarse hacia arriba