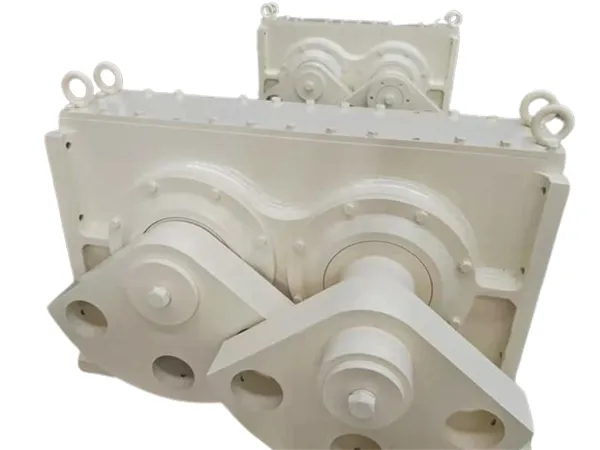

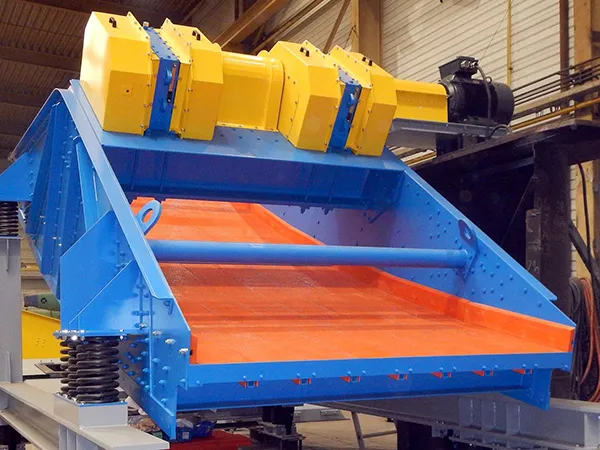

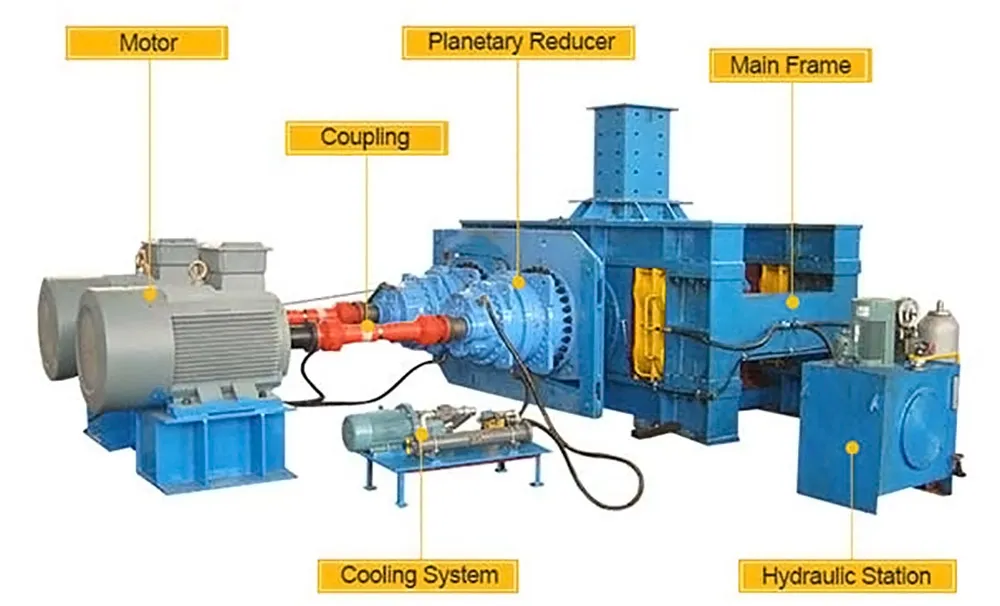

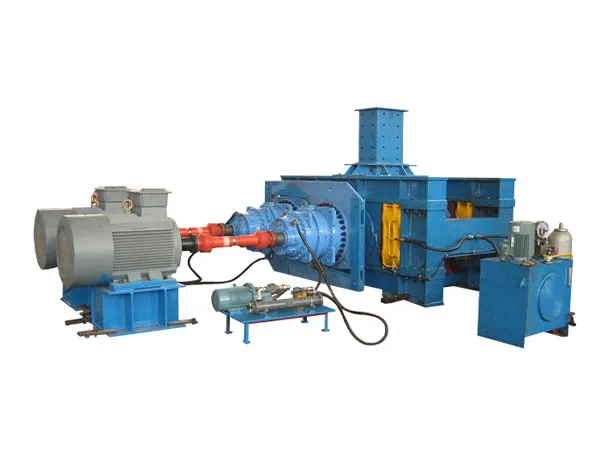

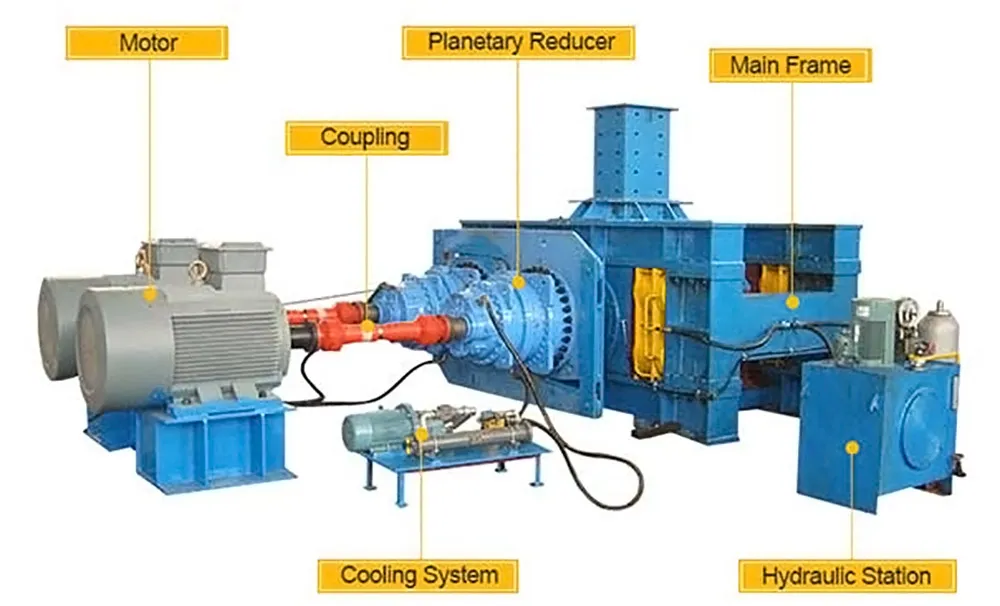

The vibrating screen exciter is a critical component responsible for generating the vibration necessary for material screening. However, during prolonged or heavy-duty operation, the exciter may experience overheating—a common yet serious issue that can affect equipment performance, reduce operational lifespan, and lead to unexpected downtime.

Exciter overheating typically results from factors such as insufficient lubrication, excessive load, bearing failure, or poor maintenance practices. Identifying the root causes and implementing preventive measures are essential to ensure the stable and efficient functioning of vibrating screens in industrial settings. An overheated vibrating screen exciter (also called a vibrator motor or shaker mechanism) is a serious issue that needs immediate attention to prevent catastrophic failure and costly repairs.

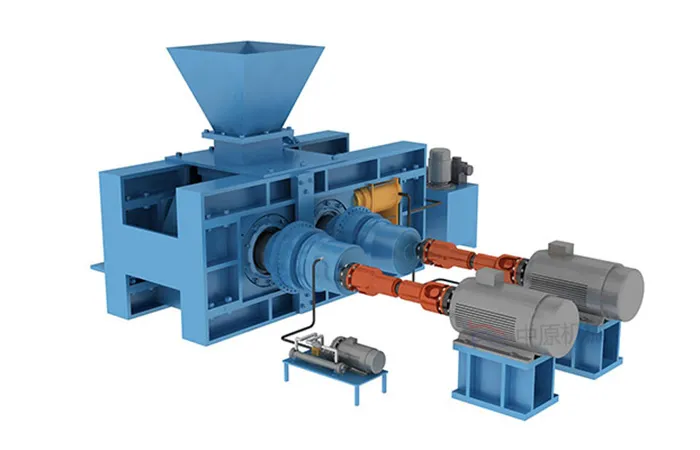

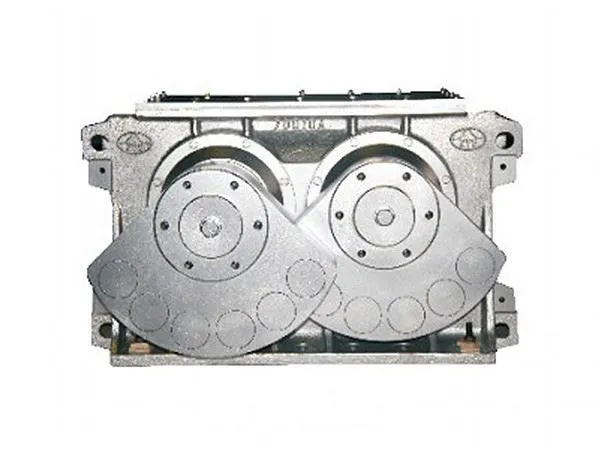

Vibrating screen exciter overheating

1. IMMEDIATE ACTION: Safety First!

STOP THE SCREEN IMMEDIATELY: Do not continue running the screen. Continued operation will likely cause severe damage to bearings, seals, and potentially the entire exciter unit or screen structure.

FOLLOW LOCKOUT/TAGOUT (LOTO) PROCEDURES: Before attempting any inspection or maintenance, ensure the machine is completely de-energized and cannot be accidentally restarted. This is critical for your safety.

ALLOW IT TO COOL DOWN: Let the exciter cool down naturally. Do not try to force cool it with water or compressed air, as this can cause thermal shock and crack components.

2. TROUBLESHOOTING (Once Cool & Safe):

Once the unit has cooled down and LOTO procedures are in place, investigate the potential causes:

Check Lubrication (Most Common Cause):

Level: Is the oil level correct (check sight glass or dipstick)? Is the grease level correct (if grease lubricated)? Both too low (starvation) and too high (churning) can cause overheating.

Type: Are you using the correct type and viscosity of oil or grease specified by the screen and/or exciter manufacturer? Using the wrong lubricant is a major cause of overheating and failure.

Condition: Check the lubricant’s condition. Is it dark, sludgy, milky (water contamination), or does it smell burnt? This indicates degradation or contamination. Consider taking an oil sample for analysis if possible.

Frequency: When was it last lubricated? Was it according to the manufacturer’s recommended schedule?

Inspect Bearings:

Overheating is often a primary symptom of failing bearings. Listen for unusual noises (grinding, rumbling) when the machine was running (if you noticed any) or try carefully rotating the shaft by hand (if possible and safe) to feel for roughness or binding.

Check the bearing housing temperature regularly (using an infrared thermometer) during normal operation as part of preventative maintenance. Compare readings to baseline or manufacturer specs.

Check for Obstructions & Cleanliness:

Is the exciter housing covered in dirt, dust, or built-up material? This can act as an insulator, preventing proper heat dissipation. Clean the exterior thoroughly.

Ensure ventilation openings (if any) are clear.

Check Alignment & Mounting:

Are the exciter mounting bolts tight? Loose bolts can cause misalignment and stress.

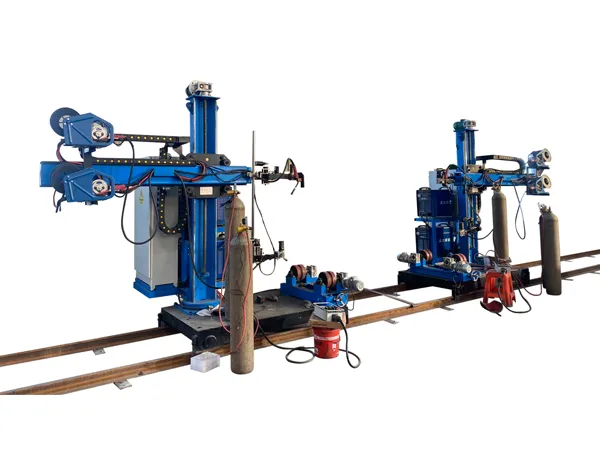

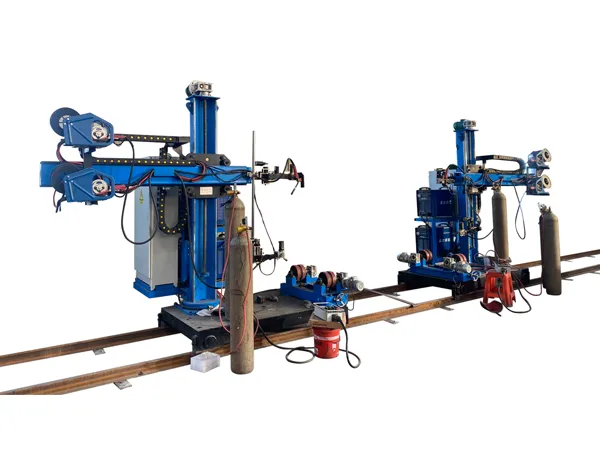

If driven by an external motor via belts or a cardan shaft, check the alignment between the motor and the exciter. Misalignment puts excessive load on bearings.

Check Drive System (if applicable):

Belts: Are the drive belts tensioned correctly? Too tight puts excessive load on bearings; too loose can cause slippage and heat. Are the belts worn or damaged?

Sheaves/Pulleys: Are the sheaves worn or damaged? Are they aligned correctly?

…

For more detailed information on how to deal with overheating of the vibrating screen exciter, please click here: https://www.zexciter.com/en/a/news/vibrating-screen-exciter-overheating.html