А молоток дробилка is widely used in mining, Представление преимуществ производительности машины для изготовления клапанных пакетов, каменный уголь, металлургия, и строительная отрасли для сокрушительного хрупкого материала, таких как известняк, шлак, и уголь. Для обеспечения стабильной работы, продлить срок службы оборудования, и сократить время простоя, Надлежащее обслуживание необходимо. Повышение дробилки молоток имеет решающее значение для его оптимальной производительности, долголетие, и безопасная операция.

Художественное обслуживание дробилки

я. Регулярные проверки (Ежедневно, Еженедельно, Ежемесячно, Ежегодно):

Молотки и стержни молотки:

Визуальный осмотр: Ищите округлый, притупленный, скольпленные края, трещины, или переломы.

Ротация: Молотки часто имеют несколько поразительных краев (2-способ или 4-й направляемый). Вращать их на новый край, когда теку. Это максимизирует их продолжительность жизни.

Замена: Замените молотки, когда все режущие края округлены или если они показывают чрезмерный износ или повреждение. Заменить молотки в сбалансированных наборах, чтобы предотвратить дисбаланс.

Молоток стержней: Осмотреть на канавку или носить. Замените, если присутствует канавка, Особенно при замене молотков подряд.

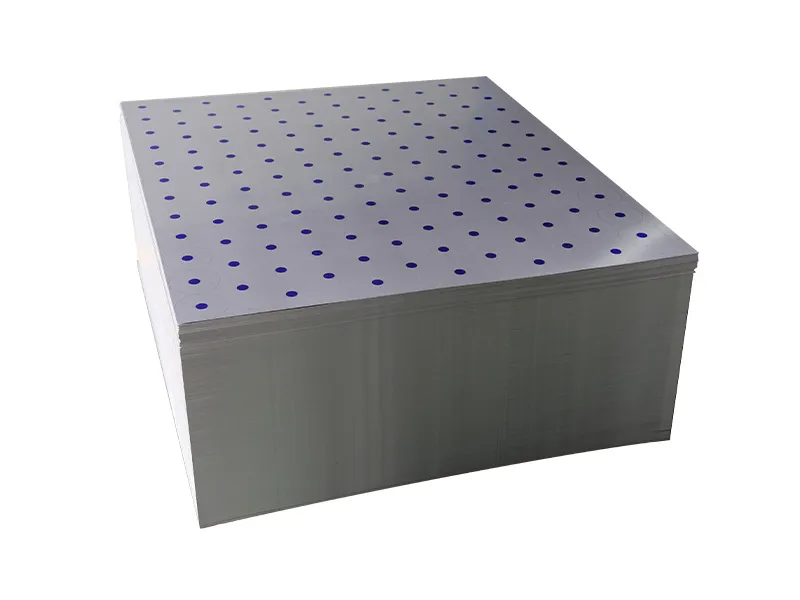

Экраны/ситовые пластины и решетки:

Износ и повреждение: Проверьте на наличие отверстий, слезы, Чрезмерное засорение, или удлиненные перфорации.

Уборка: Регулярно удалять наращивание материала, чтобы обеспечить лучшую эффективность.

Замена: Заменить экраны или решетки, когда они носят или повреждены, В качестве изношенных отверстий приводят к непоследовательному размеру частиц.

Носить тарелки/вкладыши:

Истончение: Регулярно проверять признаки истончения, particularly around the bolts.

Замена: Replace wear plates when they show signs of thinning to protect the main housing.

горелка загружается в горячем состоянии:

Signs of Wear: Check for signs of wear, перегрев (excessive heat, unusually high temperature), or vibration. Listen for unusual whines or squeaks.

Смазка: Proper lubrication is critical. Refer to the manufacturer’s guidelines for the recommended lubricant type and schedule. Избегайте чрезмерной смазки.

Замена: Replace any damaged or worn bearings promptly, often in pairs.

Motor Coupling:

Выравнивание: Check the motor coupling and its alignment every 6-12 месяцы. Смещение может вызвать вибрации.

Крепеж: Убедитесь, что монтаж и соединительные болты плотно закреплены.

Ремни:

Напряжение: Регулярно проверяйте напряжение приводных ремней. При необходимости отрегулируйте, чтобы предотвратить скольжение и обеспечить надлежащую передачу питания.

Носить: Осмотрите на трещины или признаки износа.

Крепеж (Болты, Ореховой):

Стеснение: Регулярно проверяйте и затяните все болты, орехи, и крепеж для рекомендуемых значений крутящего момента. Свободные крепежи могут привести к вибрации и повреждению.

Расход воздуха:

Чистота: Обеспечить правильный воздушный поток через мельницу. Плохое воздушный поток может снизить скорость продукта и общую эффективность.

…

Более подробную информацию о методах обслуживания дробилки можно найти в: https://www.zymining.com/en/a/news/hammer-crusher-maintenance.html