Welding positioners are devices used in various welding applications to position the workpiece at the optimal angle and orientation for welding. They come in different types and configurations to accommodate different welding needs.

Welding positioners models

Horizontal Positioner

The workpiece is placed horizontally and can be rotated around a horizontal axis. This type is useful for welding cylindrical or round objects.

Vertical Positioner

The workpiece is placed vertically and can be rotated around a vertical axis. This type is suitable for welding seams or joints on vertical surfaces.

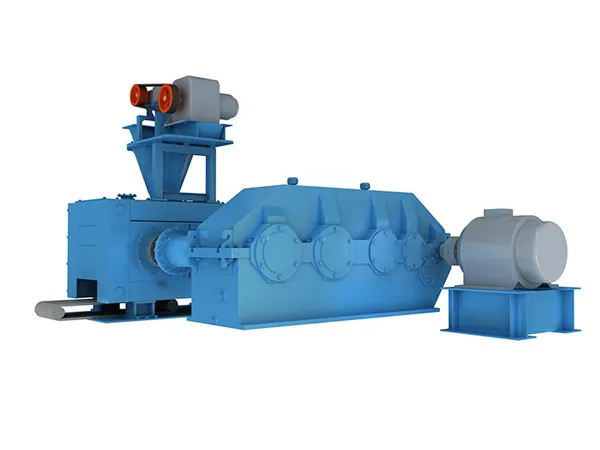

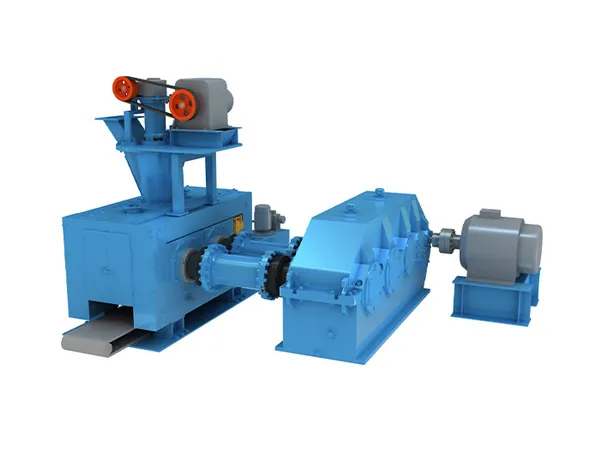

Head and Tailstock Positioner

This positioner consists of a headstock and a tailstock that supports the workpiece at both ends. It allows rotation around a horizontal axis and is often used for long and heavy workpieces.

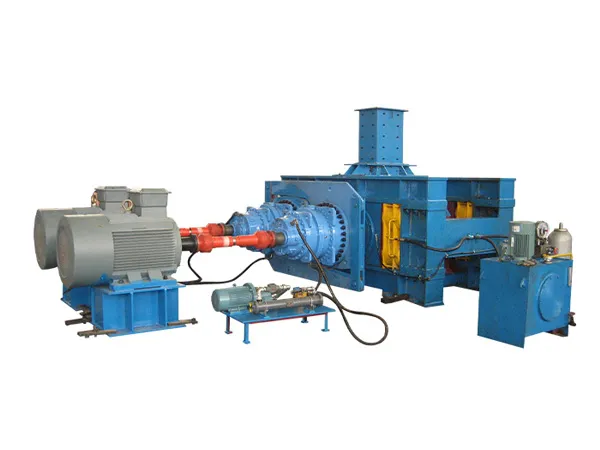

Tilt Positioner

Tilt positioners can tilt the workpiece at an angle, allowing for welding at inclined or awkward positions. They can have horizontal or vertical rotation capabilities as well.

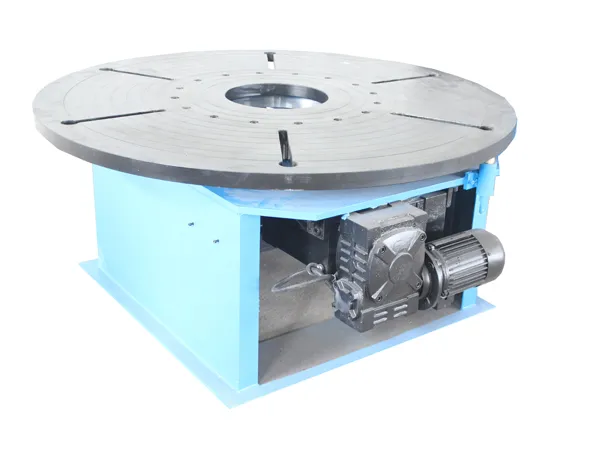

Turntable Positioner

A turntable positioner rotates the workpiece around a vertical axis. It is suitable for circular welding applications and is often used in conjunction with welding robots.

Elevating Positioner

An elevating positioner can raise or lower the workpiece to the desired height. This feature is useful when the workpiece needs to be aligned with the welding torch at a specific elevation.

…

For more detailed information about welding positioner models, please click to visit: https://www.bota-weld.com/en/a/news/welding-positioner-model.html