The production of aluminum alloy castings by the lost foam process has become an unstoppable trend. Cylinder top cover, new energy vehicle gearbox, heavy truck gearbox, etc., have gradually realized mass production in China, especially the mass production of 12-speed truck gearboxes. It marks the arrival of a new era of China’s lost foam aluminum alloy casting. The successful development of the 0.12 gearbox gearbox’s lost-mould mold has laid the foundation for its mass production.

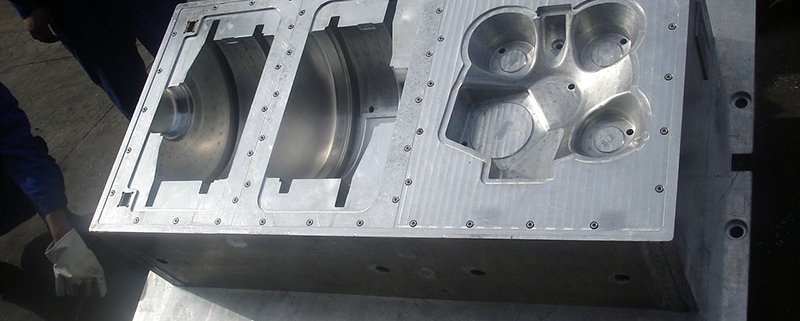

The basic structural shape of the gearbox, the product is a cavity structure, the outer part is full of reinforcing ribs, and the middle partition plate technical requirements: wall thickness 8 mm, casting material ZL101A, white mold material: EPS, castings must not have sand holes, pores, shrinkage , cracks and other defects, non-machined surface should be smooth and smooth, surface shot peening; castings using T6 solution heat treatment plus full artificial aging, casting hardness of 90-100HB castings dimensions: 589X589X404 (unit: mm), weight: 48.9 kg .

12-speed truck gearbox lost foam process casting difficulties:

1. The material is aluminum alloy, the casting temperature is 720-750 °C, the casting temperature is low, and the white mold is not easy to be gasified and liquefied.

2. The shape has many reinforcing ribs, the spacing of the reinforcing ribs is small, and it is easy to stick sand.

3, the internal partition and ribs more than oil holes, rib thickness 9.7mm, hole size: 30X27 (unit: mm), the ribs are easy to tear when forming.

4. The product is open on both sides, the internal cavity, the white mold is difficult to demould, and the anti-deformation measures should be taken during casting.

5. The shape of the box body is multi-shaped, and there are many side core inserts when the white mold is formed.

6. The coaxiality of the three bearing holes of the intermediate partition and the end face must be guaranteed.

7. The 4 sides of the box are closed, and it needs to be formed by two pieces of bonding.

In order to solve the above problems, it is necessary to introduce a lost foam mold structure of a 12-speed truck gearbox. The mold process should be consistent with the molding equipment of the foundry, conform to the lost foam casting production line of the foundry, and the complete set of lost molds of the foundry manufacturer. The production process is combined, and the mold structure adopts the following technical solutions:

Firstly determine the segmentation scheme, the structural analysis of the gearbox body, combined with the molding machine, the vibrating table, the coating, the bonding process, etc. of the casting manufacturer, the gearbox body should consider the white mold automatic molding process and the automatic bonding in the white zone section. Process. This process should focus on:

First: the white mold segmentation helps to automatically release the mold. The white mold adopts the cylinder automatic ejection mechanism during molding. The cylinder acts on the ejector rod and the stripper plate, so that the white mold is evenly forced to automatically push out 25mm, white mold and convex. The mold body is automatically separated, and the white mold is not deformed during the demolding process and is not displaced. Forming is stable.

Second: the white mold segmentation helps the automatic core pulling, and the inner and outer shape of the box determines its multi-side core pulling mechanism. After the piece is divided, all the side core inserts can be cylinder-assisted, so that the white mold is formed. The appearance quality is good, the efficiency is high, and it is not deformed.

Third: the white mold segmentation helps the automatic filling, and the white mold after the segmentation can effectively use the φ30mm straight-through automatic gun, which is dense in packing and uniform in density, and improves the filling speed of the white mold.

Fourth: the white mold segmentation helps to auto-heat and cool. When the white mold is formed, it can adopt automatic heating and spray cooling for a large area, so that the white mold is mature and the surface is smooth.

Fifth: The white mold segmentation helps the robot to operate. After the white mold is automatically ejected 25mm, the robot uses the suction cup to take out the white mold, and the white mold reserves enough position to place the suction cup.

Sixth: The white mold segment helps to automatically bond, the split surface is straight, no groove or inverted buckle, easy to use with automatic glue glue, easy to bond.

(Luoyang Liu’s Mould Co., Ltd. Liu Zhonghua, Zhang Guangbo)