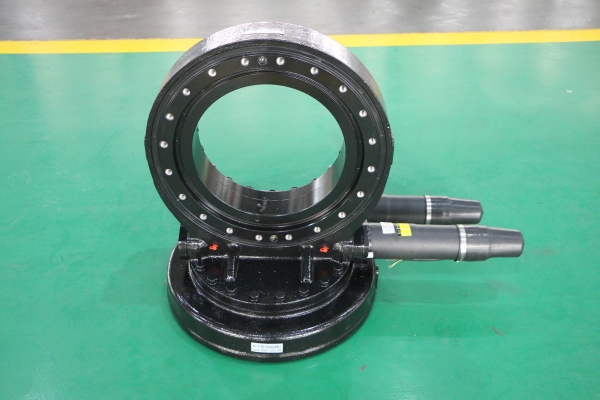

Worm gear slewing drive and spur gear slewing drive are both highly integrated modular rotary reducers. Users do not need to purchase individual parts one by one and then assemble them into products with worm gear slewing drive and spur gear slewing drive functions. Reduce unnecessary production preparation procedures, greatly improve production efficiency. In a sense, the spur gear slewing drive can replace all toothed slewing bearings. Compared with slewing bearings, it has the advantages of simple installation, easy maintenance, and greater saving of installation space.

So, what are the similarities and differences between the worm gear slewing drive and the spur gear slewing drive in the design and use?

1. Similarities:

Both the worm gear slewing drive and the spur gear slewing drive use the slewing ring as the main moving part. The slewing ring plays the role of driving the equipment to rotate and bearing the equipment load. The worm or gear is used as the driving part of the power input, the housing, the flange, the general support Bearings, seals, etc., as accessories, can finally achieve 360° rotation through reasonable design and assembly, can withstand large loads, and are components with deceleration function. Both types of slewing drives have the characteristics of slewing, deceleration, load-bearing, compact structure, fully sealed, dustproof and waterproof, modular design, and convenient installation and maintenance.

2. The difference:

1. The worm gear slewing drive uses a worm to drive the slewing support to rotate, and the spur gear slew drive uses a gear to drive the slewing support to rotate.

2. The reduction ratio of the worm gear slewing drive is large, and the reduction ratio of the spur gear slewing drive is small.

In the case of the same modulus and the same outer diameter, the reduction ratio of the worm gear slewing drive is equal to the number of teeth of the slewing ring; the reduction ratio of the spur gear slewing drive is equal to the number of teeth of the slewing ring/the number of gear teeth. The number of teeth of the gear is generally designed to be 15 teeth, and reduce The difference is 15 times.

3. The worm gear slewing drive has the characteristics of reverse self-locking, and the spur gear slewing drive cannot be reversed self-locking.

The worm gear slewing drive can only be driven by the worm to rotate the worm wheel, and the worm cannot be driven by the worm gear to rotate. The reverse self-locking makes the slewing drive widely used in lifting equipment, high-altitude operations and other equipment. Under such working conditions, the worm gear slewing drive is used No braking device is required, and the equipment can remain stationary for a long time without power. The spur gear slewing drive gear can drive the gear ring to rotate, and the gear ring can also drive the gear to rotate in reverse. It cannot achieve reverse self-locking. This feature is also used in some special fields, such as wood grabbers, snow sweepers, etc. Collision cannot be avoided during the use of the equipment, and it does not self-lock when a collision occurs, which acts as a buffer and protects the equipment.

4. The worm gear slewing drive has a low speed limit, and the spur gear slewing drive has a high speed limit.

The worm gear slewing drive is a worm gear drive, and the worm gears slide between each other. High-speed rotation is easy to generate heat, causing the worm to overheat and lock or directly damage. Generally, the rotation speed of the worm gear slewing drive does not exceed 2.5 rpm; gear type slewing drive It is the tooth-to-tooth meshing that works, it is not easy to generate heat, and the speed can usually reach 40-60 rpm.

5. The transmission efficiency of the worm gear rotation drive is low, and the transmission efficiency of the spur gear rotation drive is high.

The worm gear slewing drive has high friction between the worm wheel and the worm, and the transmission energy loss is large, so the transmission efficiency is low, usually only 30%-40%; the friction resistance between the spur gear slewing drive gears is small, and the loss is small, so the transmission efficiency is high. Generally, it can reach 90%-95%, which is very efficient and energy-saving.

6. The worm gear slewing drive has low slewing accuracy, and the spur gear slewing drive has high slewing accuracy.

The rotation accuracy of the ordinary worm gear slewing drive is affected by various factors, and can not achieve a small backlash. Generally, the precision of the precision type can reach within 0.05°; the spur gear rotation drive has high rotation accuracy, and the gears and ring gears can be grounded. The processing method can achieve high precision, and the precision of the gear type rotary drive with a diameter of 1 meter can reach within 0.01°.