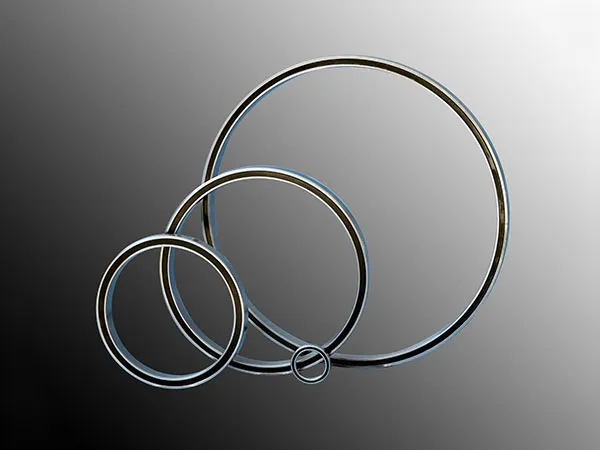

Thin-wall bearings are crucial components in industrial robots, enabling precision movement within a compact design. However, their thin cross-section makes them more susceptible to damage if not properly maintained. Extending their lifespan requires a proactive and consistent approach.

Thin-Wall Bearing Maintenance

1. Proper Lubrication: The Lifeline of Thin-Wall Bearings

Select the Right Lubricant: Choose a lubricant specifically recommended by the bearing or robot manufacturer. Consider factors like operating temperature, speed, load, and environmental conditions. Options include:

Grease: Suitable for most robot applications, offering good sealing and longevity. Ensure compatibility with seals (if present). Thin-section bearings are often shipped with a 20-30% fill of MIL-G-81322 grease for sealed types.

Oil: Can support higher speeds and offer better cooling but requires a more complex lubrication system. The oil level should typically reach the midpoint of the lowest rolling element in vertical mounts.

Solid Lubricants: For difficult-to-access bearings, consider porous polymers that release oil over time or dry film lubricants like Tungsten Disulphide or PTFE coatings.

Apply the Correct Amount: Avoid over-lubrication, which can attract contaminants, and under-lubrication, which leads to metal-on-metal contact and wear.

Lubrication Intervals: Follow the manufacturer’s recommended relubrication schedule. Adjust based on the severity of the operating conditions.

Maintain Cleanliness: Ensure the lubricant is free from contaminants. Clean the lubrication points before applying new lubricant.

2. Prevent Contamination: Shielding Against Damage

Seals and Shields: Utilize appropriate seals or shields to prevent the ingress of dust, dirt, moisture, and other debris. Inspect seals regularly for damage and replace them when necessary.

Clean Operating Environment: Minimize contaminants in the robot’s working environment.

Proper Storage: Store spare bearings in a clean, dry environment, ideally in their original packaging, to prevent corrosion and contamination.

3. Careful Handling and Installation: Setting the Stage for Longevity

Gentle Handling: Avoid dropping or subjecting bearings to impact loads during handling and installation.

Correct Tools and Techniques: Use the proper tools for mounting and dismounting bearings. Incorrect installation can lead to misalignment and premature failure.

Proper Alignment: Ensure accurate alignment of the bearing and connected components to prevent uneven load distribution and stress. Avoid excessive force during installation.

4. Regular Inspection and Monitoring: Early Detection is Key

Visual Inspections: Conduct routine visual checks for signs of wear, corrosion, damage, or leaks.

…

More detailed information about thin section bearing maintenance can be found by clicking visit: https://www.lynicebearings.com/a/blog/thin-wall-bearing-maintenance.html