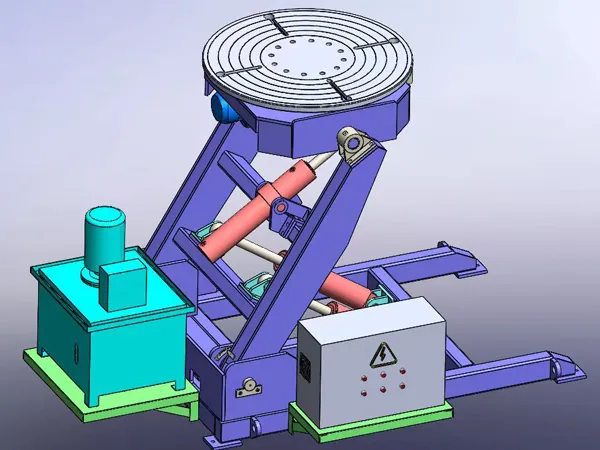

A welding positioner is a specialized piece of equipment used in welding applications to position a workpiece in the optimal orientation for welding. It helps welders to achieve better precision, accessibility, and efficiency in the welding process. The positioner allows for the rotation or tilting of the workpiece, making it easier for the welder to reach all necessary angles without having to reposition themselves.The installation of a welding positioner involves several key steps to ensure its proper setup and safe operation.

Welding positioner installation process

1. Site Preparation

Choose a location for the welding positioner that provides sufficient space for safe operation and easy access. Ensure that the floor is level and can support the weight of the positioner.

2. Unpacking and Inspection

Carefully unpack the welding positioner and inspect it for any shipping damage. Check for all the components listed in the user manual.

3. Positioner Placement

Place the welding positioner in the desired location. If it is a large or heavy unit, use appropriate lifting equipment to move it into place.

4. Leveling

Use a level to ensure that the welding positioner is perfectly level. This is critical for accurate and stable positioning during welding.

5. Securing the Positioner

Once leveled, secure the welding positioner to the floor using appropriate anchors or fasteners. This step is essential for stability and safety during operation.

6. Power Connection

Connect the welding positioner to the power source according to the manufacturer’s specifications. Ensure that the power supply meets the equipment requirements.

…

For more detailed information about the welding positioner installation process, please click here: https://www.bota-weld.com/en/a/news/welding-positioner-installation-process.html