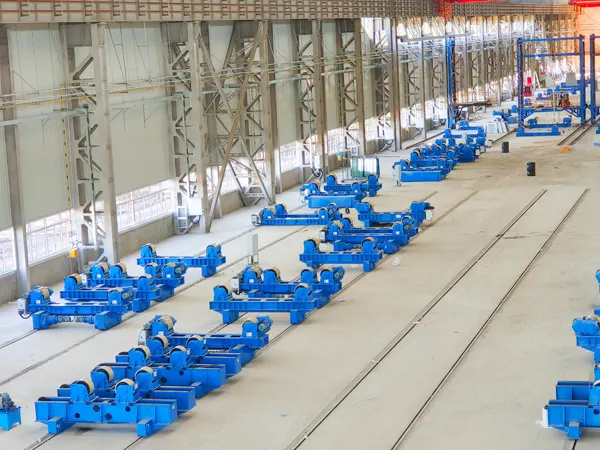

Welding rotators are essential tools in the field of metal fabrication and welding, playing a crucial role in enhancing efficiency, safety, and precision during the welding process. These innovative devices are designed to handle the rotation of cylindrical workpieces, such as pipes, tanks, and vessels, facilitating uniform welding and reducing manual labor. In this technical article, we will delve into the functionalities, types, and benefits of welding rotators, highlighting their significance in modern welding operations.

1. Introduction to Welding Rotators

Welding rotators, also known as tank turning rolls or pipe rotators, are mechanized systems designed to rotate cylindrical workpieces during welding. The primary purpose is to ensure consistent and high-quality welds by allowing for the even distribution of heat and the precise application of welding techniques.

2. Types of Welding Rotators

- a. Conventional Rotators:

Consist of two or more adjustable wheels to support and rotate the workpiece.

Manual or motorized rotation options.

Suitable for various cylindrical workpieces.

- b. Self-Aligning Rotators:

Automatically adjust to the diameter of the workpiece.

Ideal for handling varying sizes of cylindrical objects.

Improve efficiency by eliminating the need for manual adjustments.

- c. Specialized Rotators:

Designed for specific applications, such as narrow vessels or heavy-duty workpieces.

May include additional features like tilting or variable speed control.

3. Key Components and Features

- a. Drive System:

Motorized systems provide controlled and consistent rotation.

Variable speed options for different welding requirements.

…

For more detailed information about the introduction of welding rotators, please click to visit: https://www.bota-weld.com/en/a/news/welding-rotators-introduction.html