Fading of a printed aluminum sheet is a common problem, especially for prints exposed to sunlight or harsh environmental conditions. The fading is primarily caused by UV (ultraviolet) light breaking down the pigments in the ink or dyes. The specific cause and potential solutions depend on the printing method used on the aluminum.

Common Printing Methods on Aluminum

Dye-Sublimation: This is a popular method for high-quality metal prints. Dyes are infused directly into a special polymer coating on the aluminum sheet using heat and pressure. This process makes the print highly resistant to fading and scratches.

Direct-to-Substrate Printing (UV Printing): In this method, UV-cured inks are printed directly onto the aluminum surface. The ink sits on top of the aluminum rather than being infused into it.

Anodized Aluminum Printing: The image is “printed” by creating a durable, sealed image within the porous, anodized surface of the aluminum.

What to Do If Your Printed Aluminum Sheet Fades

Unfortunately, once a printed aluminum sheet has faded, it’s very difficult to restore the original colors. The color pigments have been chemically altered by UV exposure, and there is no simple way to reverse this process.

However, you have a few options depending on the situation:

Replace the Print: This is often the most straightforward solution, especially for decorative pieces. If the print has faded significantly, the best way to regain the vibrant colors is to have a new sheet printed.

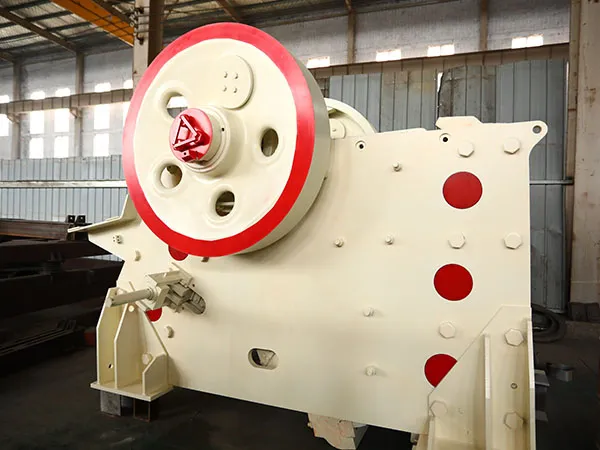

Repaint or Recoat (for non-photo prints): If the fading is on a sign, a piece of industrial equipment, or a painted surface (not a photographic print), you may be able to restore it.

Clean and Prep: Thoroughly clean the surface to remove dirt and oxidation.

Restore with a Clear Coat: Products like Everbrite Coating are specifically designed to restore the color and luster of faded, painted, or powder-coated metal surfaces. These are clear coatings with UV blockers that make the surface look new and protect it from further fading.

Repaint: If the fading is severe or the paint is flaking, you may need to sand the surface, apply a self-etching primer, and then repaint it. This is a more involved process.

Repair Minor Damage: For small, chipped areas, you might be able to use a paint pen or a Sharpie to color in the spot. This won’t be a perfect fix, but it can make the damage less noticeable from a distance.

Polish (for brushed or non-printed areas): If the fading is due to a dull, oxidized surface rather than the print itself, you can try a gentle polish by hand to remove grime and restore the luster. Be extremely careful not to polish over any printed text or images, as this can remove the print entirely.

How to Prevent Fading in the Future

Prevention is the most effective strategy. Here’s what you can do to protect your new or existing aluminum prints:

Limit UV Exposure: The primary cause of fading is direct sunlight. If possible, avoid hanging the print in a location that receives direct, prolonged sun exposure.

…

For more detailed information on what to do if the printed aluminum plate fades, please click here:https://www.dw-al.com/a/news/what-to-do-if-printed-aluminum-sheet-fade.html