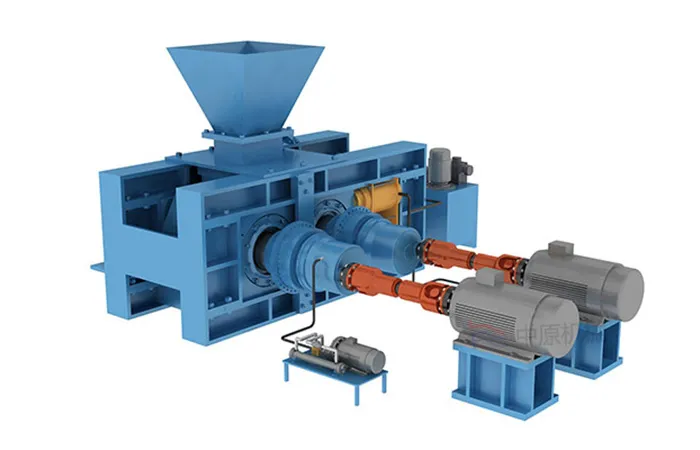

A high-pressure briquetting machine is a type of equipment used to compress powdery materials into briquettes of uniform size and shape. This machine applies extremely high pressure to compact the materials, typically using hydraulic or mechanical force. The resulting briquettes can be used for various purposes such as fuel for heating or cooking, as well as in industrial processes.

Advantage

High pressure briquetting machines are used to compress various materials, typically powders or waste materials, into compact briquettes. These briquettes offer several advantages, including:

Increased density: This makes them easier to store and transport.

Improved combustion: Briquettes often burn more efficiently and with less smoke than loose materials.

Waste reduction: Briquetting can be a way to recycle and reuse waste materials.

There are different types of high pressure briquetting machines, each suited for specific materials and applications. Some common types include:

Roller press briquetting machines: These use two rollers to compress the material between them. They are suitable for a wide range of materials and offer high production capacity.

Hydraulic briquetting machines: These use hydraulic pressure to compress the material. They are ideal for materials that require very high pressure for compaction.

Screw briquetting machines: These use a screw conveyor to feed and compress the material. They are often used for materials with low moisture content.

Working principle

Material Preparation: The raw material, which can be anything from biomass, charcoal, coal fines, or metal dust, is prepared by crushing or grinding it into a fine powder.

Mixing (Optional): Sometimes, additives like binders or other materials are added to the powder to improve the quality and cohesiveness of the briquettes.

Feeding: The prepared material is then fed into the briquetting machine’s hopper or chamber.

Pressing: Inside the machine, the material is subjected to very high pressure, typically achieved through hydraulic systems or mechanical mechanisms. This pressure compacts the material, forcing it to form into the desired shape and size.

Ejection: Once the compression process is complete, the formed briquettes are ejected from the machine.

Factors to consider when choosing a high pressure briquetting machine

Material to be briquetted: Different materials require different pressures and machine configurations.

Desired briquette size and shape: Some machines offer flexibility in terms of briquette shape and size.

Production capacity: Choose a machine that can meet your required output.

Budget: High pressure briquetting machines can be expensive, so consider your budget constraints.

…

For more detailed information about the high-pressure briquetting machine, please click here: https://www.zymining.com/en/a/news/high-pressure-briquetting-machine-introduction.html